Thermal Interface Materials

All electronic appliances generate heat. If not carefully managed, this heat can negatively affect or even damage these appliances. The performance of their electrical components deteriorates beyond certain limits and may even be completely destroyed if the temperature exceeds the acceptable temperature range. With the rise of miniaturisation and an increase in the power of individual components, thermal insulation or dissipation solutions have a central role to play.

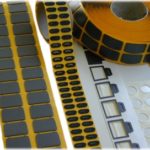

Here at Gravic Group, we offer special die-cut thermal management solutions to ensure a lifetime functioning of electronic components in electronic circuits and batteries.

Passive and active heat dissipation

Heat generated by the electronic components can be dissipated by either:

– Passive heat dissipation – a hot surface dissipates the heat itself when it comes in contact with air.

– Active dissipation (the more efficient one) – with the help of a heat sink, or a heat dissipator.

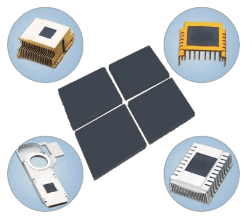

Heat sink

A heat sink is a piece of metal with a large surface area that comes in contact with air to dissipate the heat. The bigger the area is, the quicker the heat transfer happens. If we place the device and the heat sink together, the air between them will act as the insulation. To help this process, Thermal Insulation Materials (TIMs) are inserted between the device and the heat sink to transfer the heat from surface A to surface B as quickly as possible.

Thermal Interface Materials (TIMs)

Thermal Interface Materials (TIMs) reduce the thermal resistance between two contact surfaces. The thermal conductivity of a material is a measure of its ability to conduct heat. The thermal resistance through the material itself is an internal resistance, which depends on the following factors:

• material thickness

• thermal conductivity

• surface area

– Who requires TIMs?

All manufacturers of electronic components and electrical equipment e.g. computers, mobile phones, e-mobility, require TIMs to ensure they are able to dissipate heat produced by the electrical circuits.

To prevent the creation of hot spots in mobile phones, manufacturers cover the whole surface with a TIM which transfers and spreads the heat to the cover of the phone.

In electrical car batteries, between each battery cell, there is a TIM.

– What are TIMs made of?

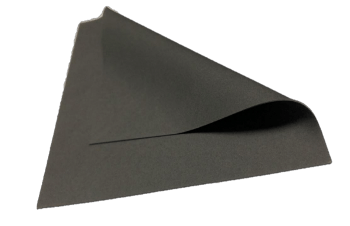

The main purpose of TIMs is to fill the gaps. The choice of materials depends on how thin or thick the gap is. To make sure that there is no air, any material needs to be pressed.

At Gravic, we often use a wide variety of TIMs, to name just a few:

– silicone pads, when softness is required,

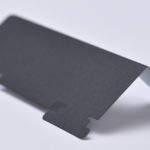

– graphite, as it’s best for spreading (but it’s very thin and might not be moldable enough to conform to the required shape),

– phase change materials (PCMs),

– acrylic pads,

– double side thermal transfer adhesives.

Innovative Thermal Materials

We have recently started developing a new compound, which is a mix between thermoplastic and graphene which produces thermo conductive plastic. This material isn’t widely available for use yes, apart from automotive activity in China,

Benefit from best advice, pricing and customer service

Ultimately, the choice of a TIM will depend on the gap size and the thermal performance you want to achieve.

At Gravic Group, we will advise you on the most suitable TIM that will fit your project.

Get in touch and let’s choose the best thermal management solution for you.

To find out more, please explore our Thermal Management Catalogue 2020

https://gravicgroup.com/wp-content/uploads/2020/07/Thermal_Management-Brochure-2020_web.pdf

Heat sink

A heat sink is a piece of metal with a large surface area that comes in contact with air to dissipate the heat.

Hot Spot

A hot spot is a commonly occurring thermal phenomenon and refer to the areas within electrical enclosures that are not cooled by forced convection. Hot spots are a result of undercuts or impediments in the path of airflow that prevent air from reaching certain concealed spots within the enclosure.

We are grateful for our close collaboration, and we are committed to continuing to evolve and progress to meet your requirements!

Improve your life with Gravic!

Share this post:

Recent posts

-

GRAVIC HUNGARY SAJTÓKÖZLEMÉNY

25/04/2023 -

Adhesives Part 2

30/03/2022 -

Adhesives Part 1

10/01/2022 -

Industrial Lamination

29/11/2021 -

Foam Gaskets

15/10/2021 -

Heat Shields

14/09/2021