Printed Electronics

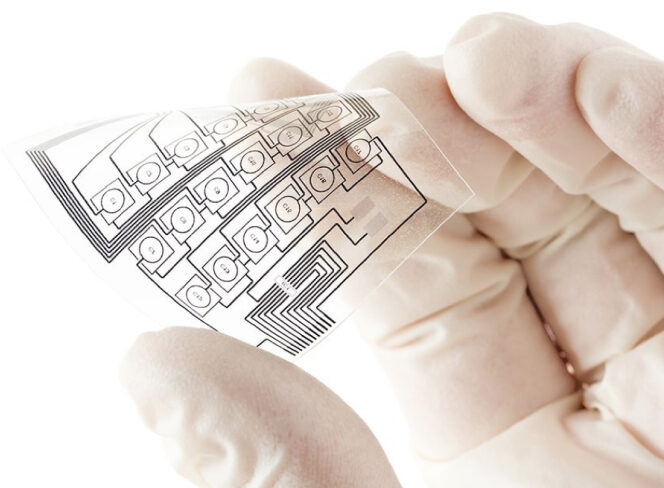

Printed electronics makes possible to produce electronic components using printing process (screen printing or digital).

It opens the way to numerous innovations and finds applications in many fields: consumer goods, house old equipment, medical, automotive, aerospace, etc.

This technology offers many advantages and interests compared to “traditional electronics”

- Significant optimization of manufacturing costs,

- Design flexibility / Innovation. It allows creation of electronic components on a variety of media, including flexible, clear, 3D parts (touch screen) …

- Ease and speed of producing prototypes with limited investments,

- Customization and production on demand,

- Reduction of the carbon footprint: this is an addictive and non-subtractive technology, so limiting waste and the use of chemicals

-

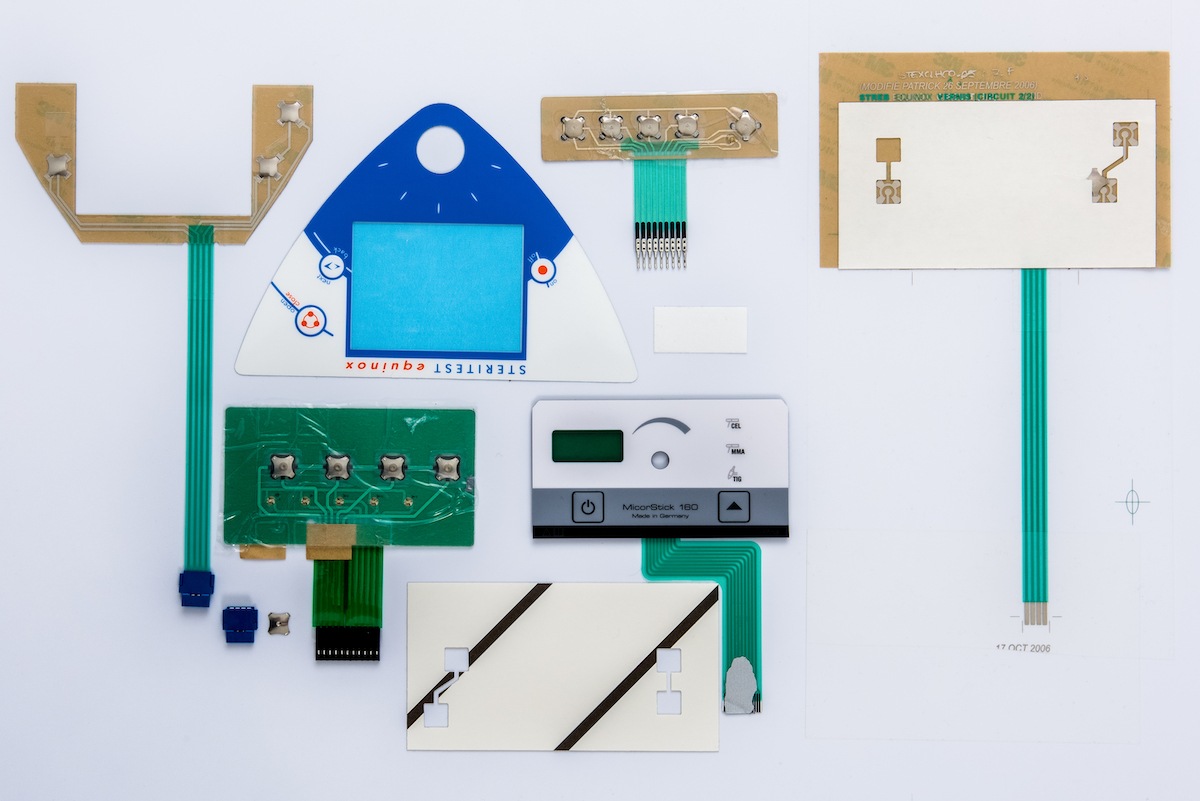

Membrane switch, keypads and flexible panel

Membrane switch, keypads and flexible panel -

The membrane keypad or flexible keypad is a human-machine interface. Less bulky and more economical than a mechanical keypad, it can be customised to meet customer needs. It connects directly to the motherboard via a flexible tab, called a ribbon cable, and connectors. It consists of a stack of front faces and a printed circuit board connected by a spacer.

The membrane keypad or flexible keypad is a human-machine interface. Less bulky and more economical than a mechanical keypad, it can be customised to meet customer needs. It connects directly to the motherboard via a flexible tab, called a ribbon cable, and connectors. It consists of a stack of front faces and a printed circuit board connected by a spacer.The flat membrane keypad

Electrical contact is made between a conductive silver pad printed on the front face or upper circuit and the silver contact printed on the lower circuit. The sensation of touch is limited when the keys of this type of membrane keypad are activated.The membrane keypad with metal spring cups

Electrical contact is made between a metal cup inserted between the front face and the printed circuit. This type of flexible keypad offers a sensation of touch when the keys are activated.The membrane keypad with embossed keys

Electrical contact is made between a conductive silver pad printed on the front face and the printed circuit. This type of membrane keypad offers a sensation of touch by deforming the pre-embossed key, with goffering or finger guide. Different options are possible for these types of membrane keypads:- Integrated CMS LEDs allowing the lighting of certain functions

- Water and dust resistance

- Shielding (to avoid electro-magnetic discharges)

- Motherboard connectors

- Flexible keypads

SPECIFICATIONS

TYPES OF APPLICATION- All machine control applications

- Vending machines

- Remote controls

- Games

TYPES OF MATERIALS- Polyester

- Polycarbonate

Which types of products should a membrane keypad be designed for?

One of the most common examples of usage for membrane keypads is undoubtedly the laptop. For these devices, and any computer in general, the keypad constitutes an essential interface between the machine and the user in the same way as the mouse, for example. Although keyboards have evolved since the first models and are constantly being reinvented (as evidenced by the recent flexible keyboards, useful for the most portable peripherals), the keyboard remains a widely-used interface adopted by all. Of course, a membrane keypad can be integrated with many other electronic and industrial devices. They are found in many machines and workstations in all industrial sectors. Membrane keypads may differ greatly from the models used for computers: Gravic Group is able to offer you bespoke keypads that are cut and screen-printed in order to precisely meet your specifications.Understanding the difference between a flexible keypad and a mechanical keypad

Mechanical keypads and membrane keypads are the two main types of keypad that can be found for both personal and professional use. A mechanical keypad consists of two clearly separate parts: the body of the device, where there is a computer switch for each key, and the keys themselves. The keys are therefore removable and, when typing, are pressed to come into contact with the switch and activate it, thus sending the associated information to the motherboard. In the case of a flexible keypad or with membranes, the dissociation between the different parts of the device is less effective. The membrane keypad consists of several layers of polyester, one of which is for the printed circuits, another for the keys, another for any LEDs or decorations… When the membrane keypad is pressed, the key rebounds and activates the circuit in question. This “layered” design in a polyester material makes it possible to reduce the noise of the keypad, but also its design costs, which make flexible keypads an excellent human/machine interface solution.

123, Zone Industrielle de l’Argile II, 06370

Mouans Sartoux, FRANCE

Tel. +33 (0)4 93 75 75 34

深圳市格瑞维克电子科技有限公司

深圳市南山区南山街道向南社区海德二道470号海德大厦A1002A

Shenzhen, CHINA