Thermal Structural adhesive

Home -> Thermal Structural adhesive

Thermal structural adhesive, also known as thermally conductive structural adhesive, is a specialized type of adhesive designed to provide both strong bonding and efficient heat transfer capabilities. These adhesives are formulated with thermally conductive fillers, such as ceramic, metal, or carbon particles, that enable them to dissipate heat while securely bonding two substrates together.

Key characteristics and uses of thermal structural adhesive:

- High Bond Strength: Thermal structural adhesives offer excellent bonding strength, creating robust and durable connections between various substrates, including metals, ceramics, plastics, and composites.

- Thermal Conductivity: The thermally conductive fillers in these adhesives allow for efficient heat transfer between the bonded surfaces. They help to bridge gaps and voids, ensuring a more direct thermal path for heat dissipation.

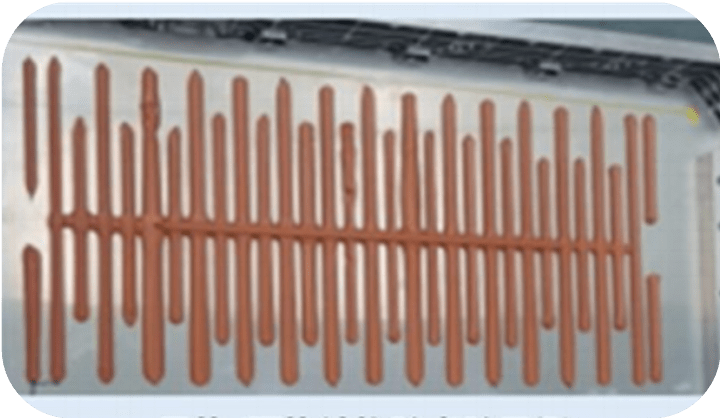

- Gap Filling: Thermal structural adhesives can fill gaps and irregularities between substrates, providing a uniform bond line and improving heat transfer across the entire interface.

- Temperature Resistance: These adhesives are designed to withstand high operating temperatures without losing their adhesive properties or compromising the structural integrity of the bonded assembly.

- Electrical Insulation: Many thermal structural adhesives are formulated to be electrically insulating, preventing the risk of electrical short circuits when bonding electrical components.

Thermal structural adhesives find applications in various industries, including:

- Electronics: They are used in electronic devices to bond heat sinks and other thermal management components to CPUs, GPUs, power modules, and other heat-generating components.

- Automotive: Thermal structural adhesives are employed in automotive assemblies to bond heat exchangers, electronic modules, and battery packs, improving thermal performance and overall structural integrity.

- Aerospace: These adhesives are used in aerospace applications for bonding components in high-temperature and high-stress environments.

- Power Electronics: In power electronic devices, thermal structural adhesives help improve heat dissipation and reliability.

- LED Lighting: They are used to bond LED modules and heat sinks in high-power LED lighting applications.

Using thermal structural adhesives offers several benefits:

- Improved Heat Dissipation: By providing a thermally conductive path between components, thermal structural adhesives help dissipate heat more effectively, reducing the risk of overheating and improving the performance and reliability of electronic devices.

- Elimination of Mechanical Fasteners: These adhesives can replace traditional mechanical fasteners, such as screws and bolts, providing a more streamlined and aesthetically pleasing design.

- Enhanced Structural Integrity: In addition to thermal performance, thermal structural adhesives contribute to the overall structural strength of bonded assemblies.

It is essential to follow the manufacturer’s guidelines and recommended curing processes when using thermal structural adhesives to achieve optimal performance and reliability. Proper surface preparation and adhesive application are crucial to ensure a successful and long-lasting bond.

Thermal conductivity: 1.2 ~ 3.0 W/(m· K)

Service life: >25 years

Resist to fire and high temperature: >1200 ◦C (become ceramic >450 ◦C)

Application:

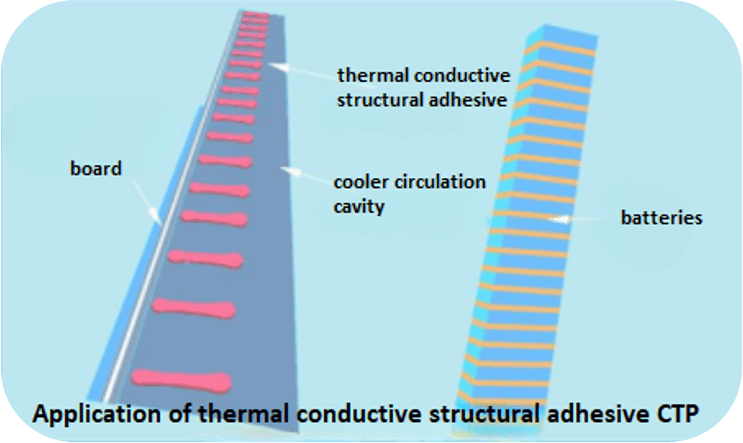

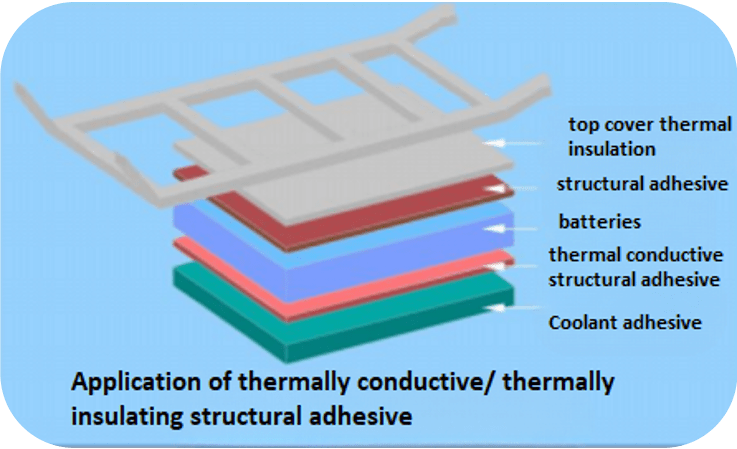

EV battery such as CTP/CTB/CTC

Polyurethane

Thermal conductivity: >1.2 or >0.6 (W/m.K)Shear adhesion strength: >8 MpaBreakdown voltage: ≥10 KV

Application temperature: -45 ◦C to +60 ◦C

Fire resistance: UL94 V-0

Modified epoxy

Thermal conductivity: >1.2 or >0.6 (W/m.K)

Shear adhesion strength: >8 Mpa

Breakdown voltage: ≥25 KV

Service life: 25 years

Modified epoxy – ceramic

Thermal conductivity: >1.2 or >0.6 (W/m.K)

Shear adhesion strength: >8 Mpa

Resist to fire and high temperature: >1200 ◦C (become ceramic >450 ◦ C)

Service life: 25 years

123, Zone Industrielle de l’Argile II, 06370

Mouans Sartoux, FRANCE

Tel. +33 (0)4 93 75 75 34

深圳市格瑞维克电子科技有限公司

深圳市南山区南山街道向南社区海德二道470号海德大厦A1002A

Shenzhen, CHINA