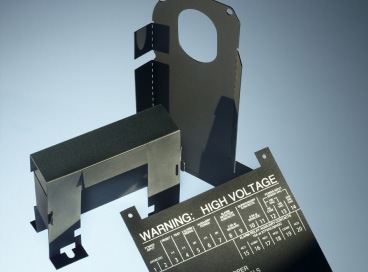

Insulators and Shielding

Home -> Converting -> Insulators and Shielding

Electrical insulator materials are essential for the electrostatic or electromagnetic separation of components or simply to provide thermal insulation, particularly for electronic and computer equipment. Contact one of our experts now to order electrical insulation or thermal pads. We have proven expertise in many types of insulation: FR700 or UL 94 VO insulation, heat sinks, etc.

We provide different insulating solutions for EV Batteries.

-

EMI Shielding gaskets

EMI Shielding gaskets -

EMI (Electromagnetic Interference) shielding gaskets are specialized sealing components used in electronic devices and enclosures to provide protection against electromagnetic interference and radio frequency interference (RFI). These gaskets are designed to create an electrically conductive barrier that prevents the leakage or transmission of electromagnetic signals into or out of electronic equipment.

Electromagnetic interference can be detrimental to the proper functioning of sensitive electronic components, leading to malfunctions, data corruption, or signal disruptions. EMI shielding gaskets help mitigate these issues by blocking or redirecting electromagnetic radiation, maintaining the integrity of electronic systems.

Key features and functions of EMI shielding gaskets:

- Material and Design: EMI shielding gaskets are typically made from conductive materials such as metal-filled elastomers, conductive foam, or wire mesh. These materials are chosen for their electrical conductivity and flexibility, enabling the gaskets to conform to irregular surfaces and provide effective sealing.

- Conductive Sealing: When placed between two mating surfaces, such as a cover and a chassis or a door and an enclosure, EMI shielding gaskets create a conductive seal. This seal acts as a barrier, preventing electromagnetic radiation from escaping the enclosure or entering it from the outside.

- Compliance and Compression: EMI shielding gaskets are designed to maintain reliable electrical contact between the mating surfaces even under compression. The gaskets are often engineered to provide consistent performance over a wide range of compression forces to accommodate various enclosure designs and tolerances.

- Environmental Sealing: In addition to EMI shielding, some gaskets also offer environmental sealing capabilities, protecting the electronic components from dust, moisture, and other contaminants.

- Customization: EMI shielding gaskets can be customized to fit specific enclosure shapes and sizes, ensuring optimal coverage and protection.

EMI shielding gaskets find application in various industries, including telecommunications, aerospace, defense, medical devices, automotive electronics, and consumer electronics. They are used in devices such as smartphones, tablets, computers, medical equipment, military communication systems, and automotive control units.

Overall, EMI shielding gaskets play a critical role in maintaining the electromagnetic compatibility (EMC) of electronic devices and ensuring their proper and reliable operation in environments with high levels of electromagnetic interference.

-

Conductive foils, fabrics, foams and film tapes

Conductive foils, fabrics, foams and film tapes -

Conductive foils, fabrics, foams, and film tapes are specialized materials designed for electromagnetic shielding and electrical grounding applications. They possess electrical conductivity, which allows them to dissipate or block electromagnetic interference (EMI) and radio frequency interference (RFI) in electronic devices and components.

Conductive Foils:

- Conductive foils are thin sheets or tapes made from metals like copper, aluminum, or tin-plated copper. These foils have a conductive surface that provides excellent electrical conductivity and shielding properties. They are often used for applications requiring lightweight and flexible shielding, such as in cable assemblies, printed circuit boards (PCBs), and electronic enclosures.

Conductive Fabrics:

- Conductive fabrics are textiles woven or coated with conductive fibers, typically made of materials like silver, copper, or stainless steel. These fabrics offer both electromagnetic shielding capabilities and flexibility, making them suitable for applications where conformability and softness are essential. Conductive fabrics are commonly used in garments for electromagnetic radiation protection, such as in military uniforms or medical shielding garments.

Conductive Foams:

- Conductive foams are foam materials infused with conductive particles or coatings, providing electrical conductivity while maintaining their cushioning and sealing properties. These foams are used to provide EMI shielding and grounding in electronic devices and enclosures. They are especially useful in applications where both electrical insulation and shielding are required.

Conductive Film Tapes:

- Conductive film tapes are adhesive tapes with a conductive layer, often made of metal or conductive polymers, coated on one or both sides. These tapes are used to bond conductive surfaces or create electrical connections between components. Conductive film tapes are commonly used in electronic assembly, grounding applications, and EMI shielding of seams and gaps.

Key properties and benefits of conductive foils, fabrics, foams, and film tapes include:

- EMI Shielding: These materials provide effective electromagnetic shielding, preventing interference from escaping or entering electronic devices.

- Electrical Grounding: Conductive materials enable proper electrical grounding, ensuring the dissipation of electrical charges and minimizing the risk of electrostatic discharge (ESD).

- Conformability: Some materials, like conductive fabrics and foams, offer flexibility and conformability, allowing them to be applied to various shapes and surfaces.

- Lightweight: Conductive foils and tapes are lightweight, making them suitable for applications where weight is a concern.

- Versatility: These materials can be used in various industries, including electronics, telecommunications, aerospace, medical, and automotive, for EMI shielding and grounding purposes.

Conductive foils, fabrics, foams, and film tapes play a crucial role in ensuring electromagnetic compatibility (EMC) and protecting sensitive electronic components from electromagnetic interference and ESD. They are widely used in electronic devices, communication systems, medical equipment, and other applications where electromagnetic shielding and grounding are essential.

- Insulation papers and films (Nomex / Formex / Mylar films) https://gravicgroup.com/en/printed-and-cut-parts/thermal-and-electrical-management/electrical-insulation/

- Kapton polyimide films:

Kapton is a brand name for a type of polyimide film or tape manufactured by DuPont. It is a high-performance polymer material known for its exceptional thermal stability, electrical insulation properties, and mechanical strength. Kapton polyimide films and tapes are widely used in various industrial applications, particularly in electronics, aerospace, and other high-temperature environments.

Key characteristics of Kapton polyimide films and tape include:

- Thermal Stability: Kapton films can withstand extreme temperatures, ranging from very low cryogenic temperatures up to high temperatures exceeding 400 degrees Celsius (750 degrees Fahrenheit). This exceptional thermal stability makes them suitable for use in extreme environments where other materials would degrade or lose their properties.

- Electrical Insulation: Kapton is an excellent electrical insulator, which means it does not conduct electricity. This property is critical in applications where electrical components need to be isolated or protected from each other.

- Mechanical Strength: Despite being thin, Kapton films have excellent mechanical strength and dimensional stability. They are resistant to tears, punctures, and abrasion, making them durable and reliable in demanding applications.

- Chemical Resistance: Kapton films exhibit resistance to many chemicals, oils, and solvents, making them suitable for use in harsh chemical environments.

- Lightweight: Kapton films are lightweight and have a low coefficient of thermal expansion, which makes them suitable for applications where weight and dimensional stability are critical.

- Flexibility: Kapton films are flexible and can be easily formed or bent to fit various shapes and contours, making them suitable for use in intricate designs and assemblies.

Applications of Kapton polyimide films and tapes include:

- Electrical Insulation: Kapton tapes are used for insulating wires, cables, and electronic components in motors, transformers, and other electrical devices.

- Thermal Insulation: Kapton films are used for thermal insulation in electronic devices, aerospace applications, and spacecraft.

- Circuit Board Protection: Kapton tapes are employed in PCB (Printed Circuit Board) production to protect sensitive components during soldering and wave soldering processes.

- High-Temperature Tapes: Kapton tapes are used in applications where high-temperature resistance and electrical insulation are required, such as in the aerospace industry.

- Masking and Protection: Kapton tapes are used for masking and protecting surfaces during various manufacturing processes.

Due to its unique combination of properties, Kapton polyimide films and tapes are valued in industries that require reliable performance in extreme conditions, such as aerospace, electronics, automotive, and scientific applications.

Electric insulator plastic – a must for eliminating electrostatic fields

Gravic will guide you in choosing the insulating material cut out that best meet your requirements and specifications. Electrical insulators are essential for the elimination of electrostatic and electromagnetic fields that can impair the proper functioning of equipment and cause safety issues. Different standards exist for electrical insulation: FR700, Formex, UL 94 insulation, etc.

Gravic can carry out the lamination, bonding, shaping and cutting of the chosen insulating material cut out. In addition, please note that on some more sophisticated systems, it is possible to add conductivity by incorporating aluminium, copper or by printing with conductive ink.

Thermal dissipator and thermal pads: the solution for temperature fluctuations

All types of components, especially in electronics and information technology, are sensitive to temperature variations, which can lead to a reduction in the performance of certain systems and even to their deterioration. That is why the choice of an effective thermal pad is essential to properly protect your components from abnormally high temperatures that could damage them.

Indeed, with the development of electronics and the miniaturisation of components, which nevertheless continue to become more powerful, problems of overheating are frequent and the use of thermal dissipator has become essential. That is why Gravic offers a wide range of specific materials to best meet your thermal protection needs. We also offer a custom cutting service to provide you with silicone or graphite pads that will deliver the perfect solution for your requirements.

123, Zone Industrielle de l’Argile II, 06370

Mouans Sartoux, FRANCE

Tel. +33 (0)4 93 75 75 34

深圳市格瑞维克电子科技有限公司

深圳市南山区南山街道向南社区海德二道470号海德大厦A1002A

Shenzhen, CHINA