OUR HISTORY

A family company founded in 1967, the Gravic Group has been able to develop its expertise and abilities to become a leader in printing and technical cutting.

Home » Discover Gravic Group » Our history

Chronology

Foundation of Gravic in Antibes, France by Gérard Jacquemin.

Production of printed circuits and metal plates.

1967

Company’s acquisition by Patrice and Olivier Jacquemin – the sons of the founder, Gérard Jacquemin.

1997

Foundation of Gravic Tunitec – company expansion and new presence in Monastir, Tunisia

1999

Gravic France factory’s floor expansion by 5 000 sqm

2000

Foundation of Gravic Hungary – company’s further expansion and new presence in Debrecen, Hungary

2005

Foundation of Gravic Shenzhen – company’s further expansion and new presence in China

2023

The discovery of engraving on metal plates.

In 1967, Gérard Jacquemin founded Gravic, whose name is a contraction of Gravure Chimique. After beginning his career in the floral industry, he discovered engraving of metal plates somewhat by chance, and quickly identified opportunities for development, especially thanks to proximity to the IBM group located in Gaude. He began his activity manufacturing printed circuits and engraving metal plates. Computing was a fast-growing industry, and the company was quickly able to build a name and develop abroad; in 1982, it obtained the necessary certifications to export to North America. it is true that the company has always been conscious of the importance of certifications in its commercial conquest of the major French and foreign groups. In 1993, it became the smallest French company (10 employees) to obtain ISO 9002 certification.

The rising cost of metal and increasingly competitive price competition led the production site to turn to a less costly material which offered new technical prospects: plastic. With its highly qualified teams, Gravic strengthened its expertise in printing and technical cutting for major groups in the automotive, electrical, electronics and mobile telephone industries.In this latter sector, the group had its best years, from 1995 to 2000.More than 16 pieces manufactured by the group were present in Sagem and Alcatel brand telephones (protective plastic films, marking labels, etc.), and later, in Nokia mobile devices.

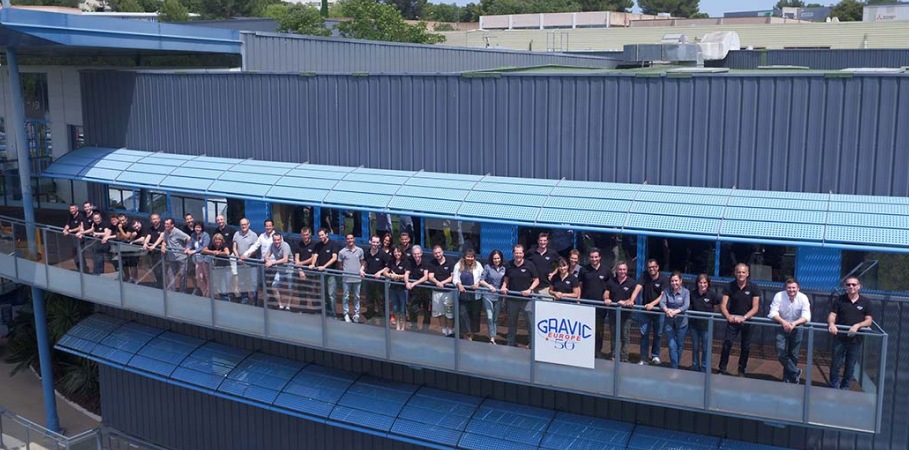

A family-owned group

Gérard Jacquemin was joined by his sons over the years, first Patrice, and then Olivier. Both were educated at American universities, and carried the torch after an LBO in 1997 to continue the development of the company, opening new international production sites, with the first one located in Tunisia in 1999.

“Our clients wanted more and more competitive prices in a very competitive market. For some of our products, we had a lot of manual operations. It was difficult to lower our prices with the labour costs in France. So we decided to create a location in Tunisia to remain competitive,” the brothers tell us.

The third location in Hungary was created to be located closer to clients. “IBM wanted us to be closer to their site in Eastern Europe. We prospected in several countries. Then, when HP, who were also one of our clients, relocated, we decided to set up a location in Hungary in 2005. We were able to get closer to our clients and to stay highly reactive.”

OUR SITES ARE ALL ON THE SAME TECHNICAL LEVEL.

WE INVEST BETWEEN 10% and 11% EVERY YEAR TO INNOVATE AND REMAIN PIONEERS IN OUR SECTOR.

Reinventing oneself in the face of challenges

2000, the year that their new factory in Mouans Sartoux was constructed, coincided with the sudden loss of one of their largest clients. In 2008 the two brothers faced it with a social plan, reducing personnel from 75 to 45, and the company entered a continuation plan, which it has come out of today.

Patrice and Olivier were both involved in researching new technologies and prospecting for clients in new sectors, and at the same time, reviewed the organisation and management process at the company. “We wanted more communication in our teams. They meet every day to review. This way, sales administration remains informed about production by technical teams, and can better respond to client questions.” Gravic Group also holds a “summit” every year, a meeting between management and sales and technical teams. “A single moment to discuss and reflect together, Sales staff share client requests and the latest market trends. The involvement of teams is a crucial element in the success of the group.”

Certifications have also been extended to the 3 production sites, and all are now equipped with the latest machinery on the market. “Our sites are all on the same technical level. We invest between 10% and 11% each year to be able to innovate and remain pioneers in our sector.”

More than 500 parts per year were delivered by the group on 4 continents, with more than 20,000 personalised products. “We produce more than 50 new products per week.”

Although most of their market share is in the fields of electronics, heat and electricity (the displays on your electrical counters are theirs!), they have been able to conquer new markets such as the cosmetics sector, and have equipped the counters of top brand with their products. “Its a market we don’t know. We usually work with major industrial groups where everything is planned in advance. Cosmetics brands require us to be more flexible and agile, and to deliver on shorter deadlines. The beginnings were a little complicated, but we were able to adapt and innovate, to become leaders in this sector today.”

123, Zone Industrielle de l’Argile II, 06370

Mouans Sartoux, FRANCE

Tel. +33 (0)4 93 75 75 34

深圳市格瑞维克电子科技有限公司

深圳市南山区南山街道向南社区海德二道470号海德大厦A1002A

Shenzhen, CHINA