Heat Shields

Multiple thermal management solutions are available today in order to manage heat efficiently. In our recent blog post we covered Thermal Insulation and talked about the materials in use nowadays. In today’s article we’ll talk about Heat Shields. It’s important to learn about this type of products, how it works and what are the benefits before ordering any. Below we’ve collected all the information to answer the most frequent questions.

What is a Heat Shield and how does it work?

A heat shield, same as insulation and any other heat preventing measures, is simply a barrier that stops or limits the heat from getting through. They protect structures from extreme temperatures and thermal gradients by two primary mechanisms. Thermal insulation and radiative cooling, which respectively isolate the underlying structure from high external surface temperatures, while emitting heat outwards through thermal radiation.

In order to choose the best heat shield for your project, first you need to identify which type of heat issue you face:

- Conductive – transmits heat from one object to another by direct contact;

- Convective – occurs when heat is transferred between a solid and a moving fluid and/or gas;

- Radiant – the heat that radiates from a heat source to a component that is not in direct contact with the heat source

Depending on the type of heat issue faced, you will find the appropriate solution from Heat Shields:

- Dissipation.

A dissipator is a special fabric or coating that is very efficient at displacing thermal energy. This solution is very useful to protect the object on the other side of the shield by reducing the amount of heat that passes through the shield or barrier. However, dissipators are a very special category that are rarely used due to their availability. - Reflection.

Reflective heat shields are the most common products used in heat mitigation. These types of products act as barriers by causing the heat to bounce off the shield’s surface away from the protected area or object. - Insulators.

These heat shields use insulation to help trap heat at its source. This is the most efficient way to improve performance and protect components.

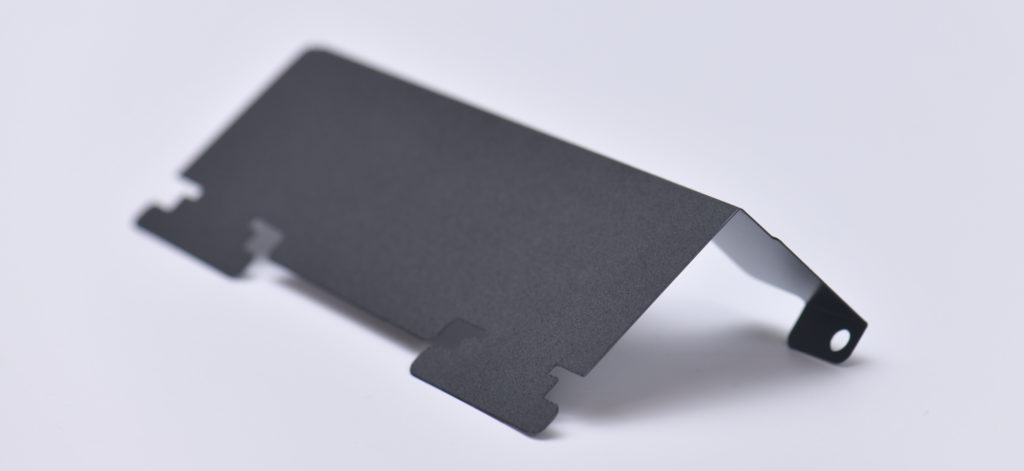

What is a Heat Shield Made Of?

We use different types of materials to produce our heat shields and insulators, but most of them are made of:

- Fiberglass and fiberglass yarn

- Aluminum

- Stainless Steel

- Silica

At Gravic Group, our duty is to make sure all of our products are effective, to the highest quality and safe.

What are Heat Shields mostly used for?

Due to the large amounts of heat caused by internal combustion engines, heat shields are used to protect components and bodywork from heat damage. This is the reason why heat shields are widely used in the automotive industry and are very beneficial to vehicles, motorcycles, various industrial settings and even for our homes.

In an industrial environment, most factory and power-plant machines produce large amounts of heat that can damage sensitive electronic components and risk workers’ health. Our heat-shield covers, curtains, sleeves, shields and tape can help to protect electronics and workers from excessive radiant heat by keeping energy trapped at the source which can help increase power and plant efficiency.

At home, ovens and fireplaces create excessive heat that can damage other furniture and appliances, such as refrigerators, cabinets, mantels, and televisions. By placing effective heat barriers over these delicate surfaces, you can increase the life of your products and prevent unnecessary damages.

In case you or your business are looking for a perfect heat barrier product, at Gravic Group, we can offer a full consultation and a free quote on our products that would be the most beneficial and customized for your needs. Contact us right now and let’s discuss your project!

We are grateful for our close collaboration, and we are committed to continuing to evolve and progress to meet your requirements!

Improve your life with Gravic!

Share this post: