Thermal Insulation

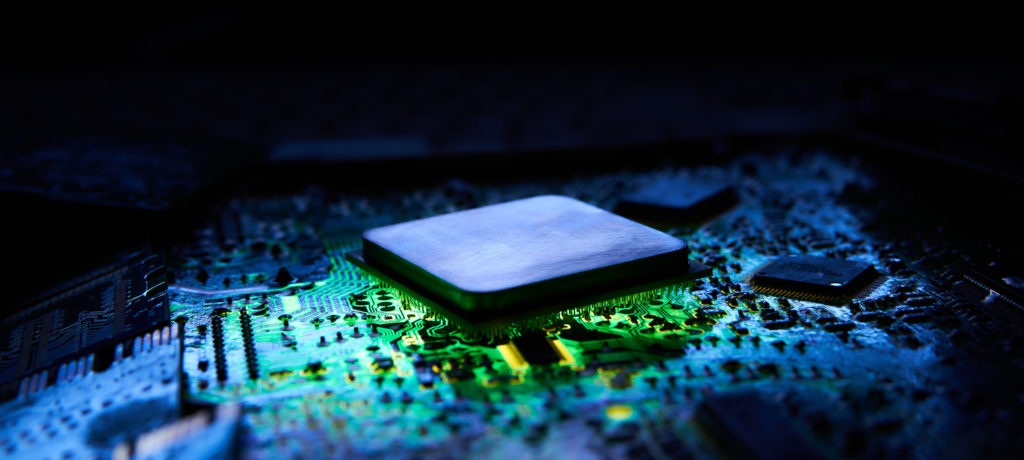

In our Thermal Interface Materials blog post, we talked about the importance of managing heat properly. If not carefully managed, this heat can negatively affect or even damage your electronic appliances. In order to prevent heat related issues and extend the operating lifetime of electronic components, multiple solutions are available today like blocking, insulating or shielding the excessive heat.

All of the solutions available have one fundamental benefit: lower energy losses leading to greater efficiency thus yielding to greater returns on investment. Investing in thermal insulation nowadays is crucial as it will help in reducing your operating costs and associated carbon footprint, plus increase your processes’ efficiency by achieving the desired performance of the products and prolonging their lifetime.

What is Thermal insulation and how does it work?

Thermal insulation is the reduction of heat transfer between objects in thermal contact or in range of radiative influence. Thermal insulation can be achieved with specially engineered methods or processes, as well as with suitable object shapes and materials.

Source: Wikipedia

Before diving into the different types of insulating materials used for high-temperature applications, let’s review a few basic concepts of thermal conduction and insulation. Heat flows between objects of different temperatures and is transferred through one of 3 methods:

• Conduction

• Convection

• Radiation

Traditionally, thermal insulation is used to limit heat transfer via conduction, where the objects are in direct contact between each other. The rate at which heat transfers between objects is determined by the thermal conductivity (k) of materials. Metals and ceramics with high thermal conductivities are often used for heat transfer applications and conversely, low thermal conductivities produce very high resistance values. For example, silica-based materials’ resistance values are less than 2 W/m-K, which means that it effectively mitigates the absorption of heat to minimize transfer.

Materials that are used in Thermal Insulation

There are a lot of different types of materials that are used in Thermal insulation nowadays, both for industrial and commercial applications. However, the main issues that they address remain the same: reducing the amount of energy, promoting sustainability through reducing CO2 emissions and generally improving the efficiency and safety.

Thermal insulation materials must be heat and fire resistant, but also be highly adaptable to a wide variety of settings and circumstances. Here are a few examples of insulation materials that are widely used:

• Mica – has natural thermal resistance, and is extremely versatile

• Fiberglass – minimizes heat-transfer and is non-flammable

• Cellulose – eco-friendly, fire-resistant and contains no oxygen

• Mineral Wool – moisture-resistant and acoustically insulating

• Polyurethane – fire-resistant and easy-to-apply

• Polystyrene – is used as an insulation material for both sound and temperature

There are many other forms of insulation which have their own set of specifications. We’ve researched each of them thoroughly so we can provide expertise on the best and the right one for your particular needs. Our history and experience allow us to find the best ways to improve your processes, control and manage heat and customize products with your unique requirements.

Here are just a few examples of Thermal Management solutions that we produce on a daily basis:

- Thermal Pad

- Phase Change Materials

- Silicon Free Thermal Pad

- EMC Foam

- Graphite

- EMI Shielding Materials (FIP Shielding Gasket, EMC Conductive Foam)

- Others (Thermal Conductive insulator/CAP, Thermal Conductive Absorber, Thermal Grease, Copper Foil, Nano Carbon Film)

Gravic Group is a leading supplier of thermal insulation solutions. Contact us for a full consultation on which products will benefit you most in your thermal management applications.

We are grateful for our close collaboration, and we are committed to continuing to evolve and progress to meet your requirements!

Improve your life with Gravic!

Share this post: