THERMAL MANAGEMENT

The thermal interface material (TIM) plays a crucial role in any thermal management solution. Despite its small physical size in most applications, it is often overlooked.

Home » Thermal Management

Thermal Interface Materials

What is Thermal Interface Material?

The thermal interface material (TIM) plays a crucial role in any thermal management solution. Despite its small physical size in most applications, it is often overlooked. However, the effectiveness of a device and its associated product heavily relies on the thermal interface material.

While many engineers prioritize heat sink design, they tend to neglect the importance of considering how heat travels from the heat source to the heat sink. Even surfaces that appear smooth have inherent surface roughness, leading to the formation of air pockets when in contact. These air pockets, due to air’s thermal insulating properties, hinder efficient heat transfer between surfaces.

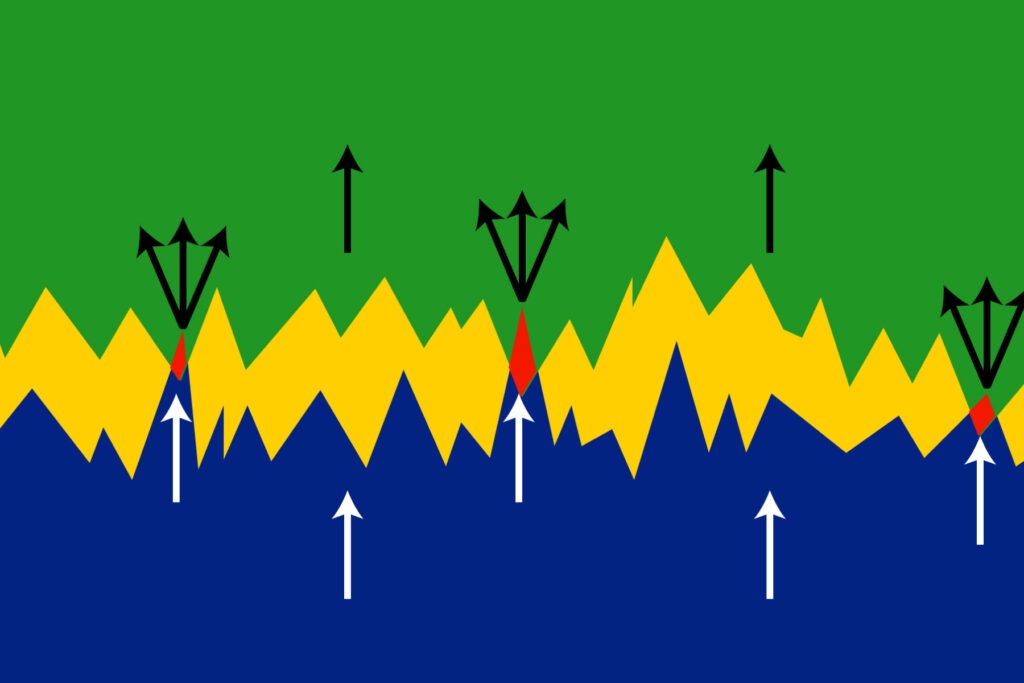

In the provided image, heat originating from the blue surface can only conduct through the highlighted red points to reach the green heat sink. The arrows visually demonstrate that heat is emitted by the entire blue surface but is limited to these contact points. The yellow areas represent the air pockets. Although heat can pass through these air pockets, the transfer is highly inefficient and significantly less compared to the conduction through the red contact points.

This concept is applicable to any electrical device, typically enclosed in a case, that dissipates heat to a metal heat sink in the absence of a thermal interface material.

What is the function of Thermal Interface Material (TIM)?

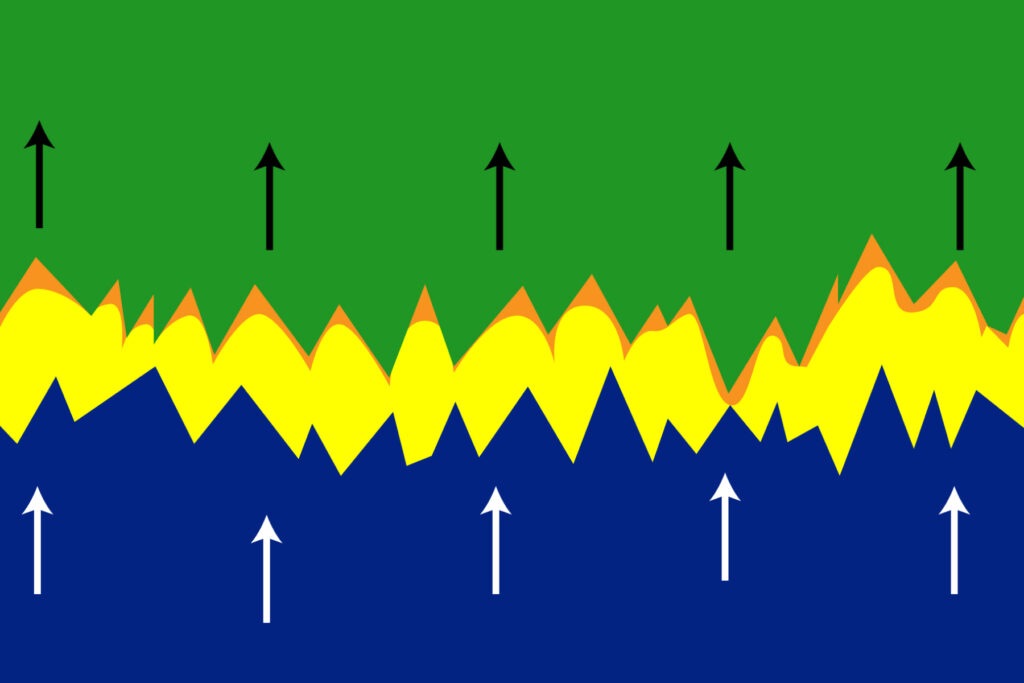

This is where the utilization of thermal interface material becomes important. Thermal interface material replaces the majority of these air pockets with a specially designed material that enhances thermal conductivity. By employing thermal interface material, we enhance the transfer of heat from the heat source to the heat sink.

In the provided diagram, the yellow area represents the thermal interface material. The presence of this material eliminates most of the orange air pockets, replacing them with a more conductive substance. As a result, heat can efficiently conduct across the entire surface, significantly improving the heat transfer away from the heat source. While it is nearly impossible to completely eliminate all air pockets, there may still be small pockets in certain areas. However, the thermal performance is greatly enhanced compared to a scenario without thermal interface material.

Thermal interface material is available in various formats and options, such as electrically isolating or electrically conductive, silicone-based or silicone-free, compliant or rigid, solid or liquid, and more. The selection of thermal interface material depends on the specific requirements of the application.

Why trust Gravic to print your industrial technical labels?

With over 50 years of experience in technical printing and converting, Gravic offers a variety of marking, branding and identification solutions of the very highest quality. You will be sure to find the product that perfectly suits your specifications amidst our wide range of industrial labels: adhesive labels, engravable tags and labels, or 3D labels for identification and branding, security labels to combat counterfeiting and wear, or even electronic RFID tags to assure tracing of your products. Whatever your needs, don’t hesitate to browse through our website or contact us to find the perfect branding or labelling solution for you.

Gravic is much more than a mere label manufacturer: we assist you throughout the production process, including design, printing, cutting, and even lamination of your industrial labels. For example, if you are looking for easy-to-place adhesive labels, or if you are in need of technical labels which can withstand high temperatures and other environmental stresses, we custom-make your perfect labels, and we guarantee fast delivery in the packaging of your choice.

What other types of products does Gravic offer?

In addition to our industrial identification labels, we also offer die-cutting and printing of technical materials for a variety of uses. Our face plates and back plates can be used as housing and protection for your products, made of a stiff or flexible plastic plate; or for filters for display screens or automotive meters, we offer the full range of die-cutting and printing processes. On our website, you can also find protective and masking films to protect your products during shipping or in use, for example.

To meet your industrial needs for a protective or watertight seal or for electrical, acoustic or thermal insulation, Gravic has developed a range of die-cutting processes for specialist technical materials, such as gaskets, silicon foams, filters, or thermal pads. These essential items for the compliance and safety of your products are custom selected and die-cut in our workshops.

123, Zone Industrielle de l’Argile II, 06370

Mouans Sartoux, FRANCE

Tel. +33 (0)4 93 75 75 34

深圳市格瑞维克电子科技有限公司

深圳市南山区南山街道向南社区海德二道470号海德大厦A1002A

Shenzhen, CHINA