Others

Midway between an ID solution and a marketing tool, a 3D adhesive label allows you to affix a visual, logo or message to an object while offering an original and effective aesthetic. Whether it is a resin dome or a more elaborate technical label (for example in Technoflex), the 3D label is a decorative addition enhanced by the relief.

Gravic, specialist in cutting and printing technical materials, produces both 3D labels and resin labels. We support you every step of the way, from design to delivery, to provide you with unique branding solutions that will truly showcase your brand image.

-

Resin dome labels

Resin dome labels -

The 3D Resin Dome label is, above all, a decorative object for use in any kind of industry. It is made by encasing a printed decorative element in a transparent polyurethane dome.

This process has several advantages:

Exceptional protection of labels against scratching, chemical products and cuts.

This resin gives labels a new visual dimension, to produce bursting colours with a magnifying effect.

Polyurethane resins are available in 3 different hardness levels – soft, medium and hard – and in a gloss or matte look.These resin domes labels can be applied to any type of support surface, and can be made in thicknesses of up to 1.6 mm.

They are available in several varieties:

Micro resin: a process used for text and fine designs (at least 2 mm)

UV resin: appropriate for small sized logos in large series (several million pieces)

Face plate with selective resin: the resin is laid partly on a front face to highlight certain areas or functions (buttons, windows, logos, etc.)SPECIFICATIONS

TYPES OF APPLICATION

- Brand logos – 3D logos

- Car – motorcycle – scooter logos

- Emblems – Badges

- Luxury – cosmetics packaging

- Device face plates

- Electrical home appliances

TYPES OF MATERIAL

- Polyester

- PVC

- Polycarbonate

- Polyurethane resin

-

3D labels

3D labels - Techno-Flex is an innovative and patented 3D relief logo. This decorative element is a showcase for the visual image of your product and brand. It is made of a polyurethane film. Unlike injected ABS logos, it adheres perfectly to curved or shaped surfaces, thanks to its flexibility. Additionally, Technoflex is more economical for small and medium series. Technoflex generally has a metallic appearance, and can also be developed in custom colours or even combinations of several colours or looks.

SPECIFICATIONS

TYPES OF APPLICATION- Brand logos – 3D logos

- Car – motorcycle – scooter logos

- Emblems – Badges

- Decoration on eyewear

- Luxury – cosmetics packaging

- Device face plates

TYPES OF MATERIAL- Polyurethane base material

-

Decals labels

Decals labels -

Dry decal labelling is a process for marking and identification which is similar to the decals used in marking on objects (plastic manufacturing, signage, decorative and advertising applications.)

It represents a good alternative to pad printing.Gravic offers you two types of transfers:

Dry transfer

The decal is positioned with a blade, using pressure to ensure that the marking is transferred to the support.

Hot transfer

The decal, made of a heat-activated “iron-on” adhesive, is transferred with the combined use of pressure and a heat source.

Gravic Group offers you manufacturing capacities which range from small series (produced on sheets or in single pieces) up to mid-sized and large series (produced in rolls).

To facilitate precise placement of the transfer, we offer:

- Special cutting of the support material, which can then be used as a template

- Printing of positioning targets

-

Printing and letter cutting

Printing and letter cutting -

Letter cutting is marking without printing: it is simply material and nothing else. Logos are the primary application of letter cutting.

Letter cutting is marking without printing: it is simply material and nothing else. Logos are the primary application of letter cutting.Gravic offers cut letters on sheets or reels. All cut letter products are delivered with an application film which ensures that letters and/or logos stay positioned until placed on the support material. This film can be cut with a special stencil to be used as a template.

SPECIFICATIONS

TYPES OF APPLICATION- Marking of household appliances

- Marking of electrical appliances

- Advertising billboards

TYPES OF MATERIAL- Vinyl (high resistance to UV / outdoor applications)

- Polyester

- Polycarbonate

-

Metal tags and plates

Metal tags and plates - The Gravic Group offers several marking solutions adapted to your constraints and needs (mechanical engraving, screen printing, chemical printing, etc.), in standard or custom formats.

Metal tags represent the origins of industrial labelling.Metal tags, used to identify or to provide tracing of industrial equipment, offer perfect resistance to external stresses (temperature, chemical products, vibrations, etc.), and ensure optimal solidity and durability. These are available in various materials (aluminium, stainless steel, brass, etc.), with various looks or surfaces (gloss, matte, anodised, satin, etc.), and may be either mechanically affixed (screws, rivets), or affixed with adhesive or glue.

Metal tags represent the origins of industrial labelling.Metal tags, used to identify or to provide tracing of industrial equipment, offer perfect resistance to external stresses (temperature, chemical products, vibrations, etc.), and ensure optimal solidity and durability. These are available in various materials (aluminium, stainless steel, brass, etc.), with various looks or surfaces (gloss, matte, anodised, satin, etc.), and may be either mechanically affixed (screws, rivets), or affixed with adhesive or glue.SPECIFICATIONS

TYPES OF APPLICATION- Sign plates

- Company plaques

- Industrial information or prevention plaques

- Serial number or bar code plates

- Identification or tracing tags

- Laser marking on metal tags

- Safety plaques

- Back plates

- CE plaques

TYPES OF MATERIAL- Ordinary, anodised, or coated aluminium

- Rustproof or stainless steel

- Brass

- Copper

- Magnetic plates

-

Thermal printing ribbons

Thermal printing ribbons -

The thermal transfer printing technology can deposit the hot-melt ink from a thermal ribbon onto all types of support materials, using heat from the print head of a thermal printer.

These thermal transfer ribbons are usually black, but also exist in other colours.

Would you like to easily and durably print your blank and semi-printed labels? In partnership with the best ribbon makers (Armor, Ricoh, and others), Gravic offers you an all-in-one solution: label + consumable.

Depending on your printers, support materials and applications, we offer you 3 types of ribbons:

Wax: AWR470

Wax thermal ribbons are often used for printing onto paper labels of a vellum type, with no coating or with a semi-gloss coating.

It is more economical, but less resistant to external stresses (scratching, chemical products, temperatures).

This type of thermal transfer ribbon is appropriate for “short-term” applications (mailing labels, logistics, or inventory).

APR 600 wax/resin

The wax and resin mixture in this thermal ribbon makes it resistant to higher temperatures (100°C), better resistant to solvents, and delivers excellent print quality on highly varied materials such as uncoated and coated paper, gloss and polypropylene synthetic materials.

AXR7+ / AXR8 / B110 resin

Resin thermal transfer ribbons offer the highest level of resistance to external stresses (scratching, chemical products, temperatures).

All types of synthetic materials (PP, PE, PVC, PET) can be printed on with these ribbons.

Additionally, the combination of certain polyester support materials and a resin ribbon guarantees perfect resistance to the most aggressive chemical products (brake fluid, motor oil, solvents, etc.)

-

Custom pre-printing of labels

Custom pre-printing of labels -

Custom pre-printing can be used to make every label a unique label. On a common base (label, metal plate, face plate, etc.), each product is personalised (with a different text, or a unique, incremental serial number, etc.)

Gravic offers custom pre-printing using 3 technologies: reprinting by thermal transfer (wax or resin) for labels delivered in rolls, or LASER reprinting and digital printing for labels delivered on sheets.

Gravic can assist you to find the most appropriate product for your needs.

Thermal transfer pre-printing to labels on reels

The label is reprinted with wax transfer (for paper-based labels), or with resin (for polymer-based labels). The pre-print is generally in black or white. The reprinted label may be blank or already printed (colour logo, legal notice, fixed values).

The label can also be coated afterward to increase the durability of the pre-print.

LASER Printer pre-printing

Gravic makes custom A4 format labels, which can be reprinted with any laser or ink jet printer.

The selection of support materials is wide, depending on your durability needs.

With existing standard or custom formats, pre-printed or not, Gravic will be able to find the most appropriate solution for your needs.

LASER Engraving

Laser pre-printing functions with a principle of aggression to the material.

The laser beam can make marks by way of several processes:

By destruction of the upper layer of two-layer materials of an acrylate type, or two-layer Gravoply®

By destruction of the anodised surface of chemically coloured plates.

By activation of pigment molecules in the material (laser polycarbonate)Digital printing

Digital printing (ink jet, offset, etc.) is achieved one print at a time, and is controlled by computer software. In this case, a number of files is created equal to the number of pieces desired.

SPECIFICATIONS

TYPES OF APPLICATION

- Inventory labels

- Company plates with serial numbers

- Multilingual labels

TYPES OF MATERIAL

- Paper

- Polymers (PET/PVC/PP/PE/PC)

- Dual-layer materials (Gravoply®/Acrylate)

- Aluminium plates with coloured backing

-

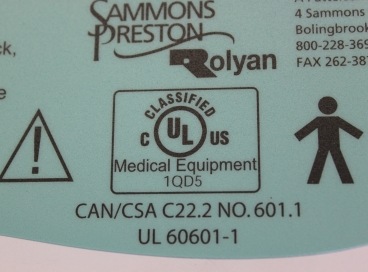

UL and CSA approved products

UL and CSA approved products -

UL and CSA approved products comply with the international standards required for export to Canada and the United States.

UL homologation provides a guarantee of safety for users of our products, in compliance with the “Marking and labeling systems – UL 969” standard.

Gravic offers a wide range of UL and CSA approved products: UL labels, UL front panel, and cut adhesive products.

A label or face plate may be UL and CSA approved if:

- it is adhesive and used as a plate or front face. (No removable intact)

- it includes information, instructions, or identification.

- its construction complies with the ANSI/UL 969 standard.

Gravic transforms and personalises safety materials which are proposed by its partners, or designs the custom product itself.

Depending on the level of safety desired, Gravic can offer the most appropriate product for your needs, whether you are looking for UL label, UL front plate or other materials.

SPECIFICATIONS

TYPES OF APPLICATION

- Electrical devices

- Home devices

- Consumer electronic devices

TYPES OF MATERIAL

- Polyester

- Polycarbonate

Customized metallic plate: what Gravic has to offer

At Gravic, we offer you a wide range of different metallic plates and labels to ensure information transparency and traceability of your industrial equipment. The plates we supply are resistant to external elements (temperature, humidity, chemical products, vibrations etc.) to guarantee that your product is consistently durable and robust. These resistance properties ensure that you get an industrial plate that is exceptionally durable and will accompany your equipment from the moment it is designed to when it is recycled.

For every industrial plate, Gravic offers you various base materials such as brass, aluminium, or stainless steel, as well as various finishes to give your plate a special aesthetic appearance: satin effect, shiny, matte, anodised etc… To ensure you get a unique, high-quality plate, we use various means of labelling for your customized metallic plate, such as chemical, metallic or laser etching, or even serigraphic printing.

Why choose Gravic for industrial plates?

Gravic, an industrial labelling specialist, allows you to enjoy the benefits of its 50+ years in the trade to make your industrial plate. Our renown with numerous clients across many different sectors is because we have always been committed to supplying you with high-quality labelling solutions at affordable prices. We are also well-known for our delivery service, since we get your custom-made metallic plate to you within 24 hours after you order! Last year, 96% of our deliveries arrived on time.

Resin dome label, long-lasting and visually attractive

Among the different 3D labels available from Gravic, the resin dome label is an effective choice for affixing visuals that have an added attractiveness for your customers. Encapsulating resin on the printed decoration of your choice gives it an original relief that is pleasant to the touch and will also protect the label from knocks and scratches.

In addition, its magnifying effect helps make the colours more vivid, combined with the finish you have chosen for the resin, either glossy or matte. The polyurethanes used in the design of these resin labels have three levels of flexibility: soft, medium and hard. You can thus customise your resin dome label so that it best matches your specifications (for example, a soft label will be preferable on a textile).

The Technoflex label: an innovative solution for your 3D labels

An evolution of the resin dome label, the technoflex label is also made from polyurethane films. Its main advantage is undoubtedly its flexibility: it adheres easily to rounded or curved surfaces without compromising the visibility of the logo or message. Its flexibility prevents any cracking or damage to the adhesive label during application. In particular, it is more economical for the production of low volumes and is ideal for luxury packaging as well as automobile logos and badges. This great versatility makes technoflex resin labels the superior choice for your 3D brandings.

123, Zone Industrielle de l’Argile II, 06370

Mouans Sartoux, FRANCE

Tel. +33 (0)4 93 75 75 34

深圳市格瑞维克电子科技有限公司

深圳市南山区南山街道向南社区海德二道470号海德大厦A1002A

Shenzhen, CHINA