Foams and Gaskets

Home -> Converting -> Foams and gaskets

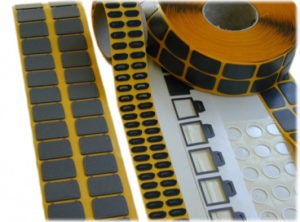

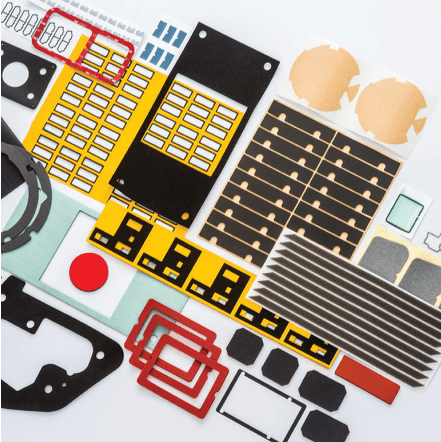

To best respond to your industrial needs, Gravic provides cutting and bonding solutions of numerous technical materials such as converted gaskets or technical foams.

Sealing, soundproofing or shock absorption are some of the properties that are essential to the proper functioning of many products and appliances. This is why we offer a wide choice of materials to address this, with a custom cutting service and even lamination if necessary.

Our high-performance technical materials are processed to match your specifications and give your product all the properties required: do not hesitate to contact us to discuss your project in case of need for converted gaskets or seals.

-

Technical and functional foam

Technical and functional foam - GRAVIC provides you with custom solutions for cutting and laminating technical foams and technical elastomers (such as poron foam) that fulfil different functions:

- Thermal protection

- Sound protection

- Electrical protection

- Impact protection

- Vibration absorption

- Anti-slip

SPECIFICATIONS

TYPES OF APPLICATION- Electronic devices and equipment

- Industrial equipment

- Automotive

- Aviation

- Bumper pads, feet

- Chocks

- Light guides

TYPES OF MATERIAL- Polyethylene (PE), Alveolite foam

- Polyurethane (PU), Korel foams

- Polypropylene (PP) foams

- PVC foams

- Laminate foams

- Silicone, Bisco foams

- EPDM foams

- Poron foams

- Rubber, EPDM, silicone

Why use technical foam?

Technical foam is useful in many different situations and industries. Its main advantage is for the protection of fragile parts or objects. Indeed, being particularly flexible, it absorbs shocks caused during transport and storage. It is used for the packaging of certain products, such as jewellery boxes, wines and spirits, as well as in the automotive sector.Trust Gravic for your technical foam

Gravic cuts and supplies parts in high-performance technical foam in a wide range of thicknesses, densities, compressive strengths and colours to meet your highest demands. The self-extinguishing capacity of the foam when exposed to a flame can also be taken into account in our design (compliance with the UL94 V0 standard for certain materials). Depending on the applications, the foams can be provided with or without laminated adhesive. Gravic, the experts in technical prints and cuts, is at your service for your cutting needs for insulating material and technical foam. -

Silicone foams

Silicone foams -

Mainly used in the fields of transport (aeronautics, railways, automotive etc.), medicine and electronics, silicone foam gaskets are high-quality materials that enable you to solve all your sealing, insulation and absorption problems in extreme conditions. This is particularly the case for Rogers foam or Bisco foam that Gravic, specialist in die cutting technical insulating materials, offers you for your protection solutions. Available in both open and closed cell versions, these silicone foams are ideal for use in high temperature resistance, fire resistance, chemical resistance, mechanical resistance and UV resistance. You can use them to protect your products and equipment by incorporating our technical foams into your production line. As a preferred partner and converter of Rogers Corporation, Gravic offers a wide range of Rogers silicone foams die-cut and bonded to your specifications. All of our Rogers Bisco foams can be customised: please contact our experts to discuss the best solution for your project. These foams, available with open or closed cells, are perfectly suited to your constraints for high temperature resistance, fire resistance, resistance to chemical products, mechanical resistance, and resistance to UV. As a preferred partner and processor for Rogers Corporation, Gravic offers you a wide selection of unique, pre-cut Bisco foams with adhesive, for your:

Mainly used in the fields of transport (aeronautics, railways, automotive etc.), medicine and electronics, silicone foam gaskets are high-quality materials that enable you to solve all your sealing, insulation and absorption problems in extreme conditions. This is particularly the case for Rogers foam or Bisco foam that Gravic, specialist in die cutting technical insulating materials, offers you for your protection solutions. Available in both open and closed cell versions, these silicone foams are ideal for use in high temperature resistance, fire resistance, chemical resistance, mechanical resistance and UV resistance. You can use them to protect your products and equipment by incorporating our technical foams into your production line. As a preferred partner and converter of Rogers Corporation, Gravic offers a wide range of Rogers silicone foams die-cut and bonded to your specifications. All of our Rogers Bisco foams can be customised: please contact our experts to discuss the best solution for your project. These foams, available with open or closed cells, are perfectly suited to your constraints for high temperature resistance, fire resistance, resistance to chemical products, mechanical resistance, and resistance to UV. As a preferred partner and processor for Rogers Corporation, Gravic offers you a wide selection of unique, pre-cut Bisco foams with adhesive, for your:SPECIFICATIONS

TYPES OF APPLICATION- Silicone watertight seals

- Thermal screens

- Fireblocks

- Sound absorbing cushions

- Anti-vibration gaskets

TYPES OF MATERIAL- Rogers Bisco foam HT-800, HT-805 foam

- Rogers Bisco cellular silicone foam

- Rogers Bisco solid silicone foam

- Acrylic adhesive

- Silicone adhesive

What are the properties of Rogers Bisco foams processed by Gravic?

Bisco silicone foams are produced by Rogers Corporation and are therefore known as both Bisco and Rogers foams. These foams are very popular in the industrial world for their multiple sealing properties, particularly acoustic, while offering good protection against vibration and shock. It is for this reason that silicone foam gaskets are regularly used in the design of electronic devices. Rogers Bisco foams are not just sealing or acoustic gaskets, they are also highly resistant to external stresses such as high temperatures, prolonged exposure to UV light and contact with chemicals. Their versatility and resistance is complemented by the ease of laser cutting: these silicone foams are therefore ideal for any industrial assembly process aimed at reinforcing your products, among other uses.Why incorporate silicone foam seals into your production line?

Ensuring the protection and sealing of your products is a necessity, especially for devices that are particularly exposed to this type of stress that can affect their performance. Historically, silicone foam gaskets have been used in electronics to prevent intrusion of water or dust. Their role as an electrical insulator is also important to ensure safe use of the product. Shock absorption is another great advantage of silicone foams, especially for products or appliances whose parts may be subject to opposing pressures or collisions during use. They are used in transport, mechanical engineering and many other industrial sectors. If you would like to speak to a Gravic expert to determine the type of silicone foam seal that is right for you, please contact us. -

Watertight Seals

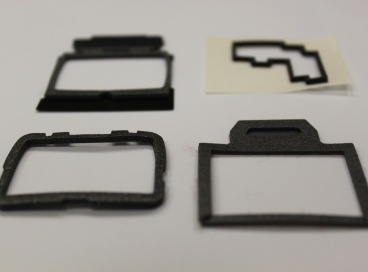

Watertight Seals - Seals against water, air or dust are often used in the electrical technical, telephony and automotive industries. The watertight seal is made of a type of insulation that isolates two different areas from each other (squeeze points or surroundings).

With good resistance over time, watertight seals also offer excellent resistance to temperature variations. Consequently Gravic, a maker of watertight seals, can design high-performance seals for you in a wide range of thicknesses, sizes, densities, resistance to compression, and colours, to meet your most exacting requirements. Depending on the application, watertight seals may be of an open or closed-cell type, with or without adhesive. Several grades of seal are available:

With good resistance over time, watertight seals also offer excellent resistance to temperature variations. Consequently Gravic, a maker of watertight seals, can design high-performance seals for you in a wide range of thicknesses, sizes, densities, resistance to compression, and colours, to meet your most exacting requirements. Depending on the application, watertight seals may be of an open or closed-cell type, with or without adhesive. Several grades of seal are available:- IP54: protection from dust and particles

- IP65: protection from dust, particles, and water projections

- IP68: Complete protection when fully immersed in water

SPECIFICATIONS

TYPES OF APPLICATION- Electronic devices and equipment

- Industrial equipment

- Sealing of irregular surfaces

- Automotive

TYPES OF MATERIAL- EPDM

- PVC foams

- Silicone

- PE

- Poron (PU)

-

Acoustic filters and Gaskets

Acoustic filters and Gaskets - Playback of sounds relies on the principle of vibrations (Laplace forces). Resonance in a loudspeaker/tweeter or foreign bodies present inside them can devastate the performance of the product. Gravic assembles and custom cuts materials to provide durable functionality for audio systems in all situations.

Acoustic filters

An acoustic filter prevents foreign bodies from getting inside loudspeakers. This filter consists of a foam, a selective adhesive, and a polyester cheesecloth. It ensures IP protection (water and dust) and may be entirely watertight.Acoustic seals

The acoustic seal “breaks” vibrations between the membrane and the coil of the speaker to ensure perfect reproduction of wavelengths. It also functions to dissipate heat from the head, which can produce sound distortion due to overheating.SPECIFICATIONS

TYPES OF APPLICATION- Speakers

- Tweeters

- Microphones

TYPES OF MATERIAL- PE foams

- EPDM

- Poron (PU)

- Silicone

- Cheesecloth

- Solid silicone

What types of seals does Gravic offer?

Mainly used to prevent the transfer of water, air or dust, seals and waterproof gaskets allow you to further protect your objects and equipment from external attack. They are used in many industrial sectors such as telephony, electronics or the automotive industry, as sealing is necessary to ensure the proper functioning of products and the safety of their users.

We also produce acoustic filters and noise insulation gaskets, which are essential in ensuring the correct functioning of audio systems. Filters prevent the build-up of foreign bodies inside the device that could affect its operation and sound reproduction. Acoustic noise insulation gaskets, on the other hand, help control air vibrations and prevent surrounding materials from disturbing it, thus ensuring the proper reproduction of frequencies.

Which technical foams does Gravic work with?

Gravic handles the cutting and lamination of numerous technical foams (such as Bisco, Rogers or Poron foams for example) which can give a wide variety of protection to your product: thermal, electrical, sound, shock protection, etc. Depending on your needs, our experts will define the type of high-performance technical foam that best suits your requirements and work with you to ensure the creation of a solution that satisfies your specifications. It is also possible to opt for silicone foam gaskets, thus also ensuring the impermeability of your products: a 2-in-1 solution that is perfectly resistant to high-temperature stress, exposure to chemical agents or U.V. radiation.

123, Zone Industrielle de l’Argile II, 06370

Mouans Sartoux, FRANCE

Tel. +33 (0)4 93 75 75 34

深圳市格瑞维克电子科技有限公司

深圳市南山区南山街道向南社区海德二道470号海德大厦A1002A

Shenzhen, CHINA