Films and surface protections

Home » Converting » Films and surface protections

Protection foils safeguard various components throughout the manufacturing cycle, final packaging process, and during transport. They protect materials against sources of external damage, scratches, soiling or breakage during handling. That’s why protection foils are so important for keeping your products in good condition, which is where scratch-resistant foiloffers a practical solution for improving durability. Gravic, specialist in cutting techniques, also provides a range of screen protection foils to protect your surfaces against breakage and spillage, perfect for manual work and production lines.

-

Display foils

Display foils -

A screen protection foil or film provides a solution for invisible protection of the surface of the screen from scratches, fingerprints, impacts, and any external stresses. Therefore, this is an economic solution that is easy to apply and protects your devices from getting damaged during transportation and usage.

This premium quality touchscreen protection foil is easily to apply manually or automatically, at the same time ensuring a completely flat surface that is free from air bubbles. Its highly effective resealable adhesive also ensures that no glue residues remain stuck to the screen. Gravic protection foils can be both personalised and tailor-cut to suit your exact needs. Their other advantages are their customized printing and expiry date tags.

The mark of high quality in a protective film for touch screens is its ease of manual or automatic placement, which ensures a smooth surface, free of air bubbles. Its high-performance removable adhesive guarantees that no residual glue remains on the support.

Gravic can offer you customisable printing onto these films, and an application spline.

Why put a screen protection foil on your devices?

Screens are fragile components: the slightest knock can scratch or break them, and they are especially sensitive to dust or water. To make your screens (and therefore ultimately your devices) more durable, adding a screen protection foil is strongly recommended. This protection will be effective at every moment, from the production phase to product transport and end usage.

Gravic, a specialist in material cutting techniques, can supply you with protection foils that are adapted to your specific terms of reference. Our films are pre-cut to fit the dimensions of your screen as well as all components, buttons, or interfaces that the foil should not cover. Moreover, our screen protection foils can be printed in a personalised design, for example if you wish to have a logo or slogan displayed on your screen.

Can I include a protection foil application stage in my production line?

We attach great importance to the ease with which our screen protection foils can be applied. Whether your application process is automatic or manual, our adhesive films can always be re-sealed if necessary and they do not leave any unsightly glue residues on your screen. You can therefore add a protection foil application stage to your production processes without needing to worry. If you are looking for a more temporary solution, such as a foil to be removed later by the end user, do have a look at our removable foils, since these might be more suited to your needs.

-

Optically clear films

Optically clear films -

Optical clear surface protection films, commonly known as screen protectors or protective films, are transparent sheets made of materials like tempered glass or specialized plastics that are designed to safeguard the screens of electronic devices, such as smartphones, tablets, laptops, cameras, and even some larger displays like TVs and monitors. These films provide a layer of defense against scratches, fingerprints, dust, and minor impacts while maintaining the optical clarity and touch sensitivity of the device's screen.

Overall, optical clear surface protection films offer an extra layer of protection to keep your devices' screens looking new and free from scratches, while maintaining their visual quality and touch responsiveness.

Gravic prints, caps and cuts backlight filters. Gravic also brings its experience and expertise to bear, by making its colour analysis laboratory available to its clients (LAB analysis / light transmittance / wavelengths / bandwidth / etc.)

Backlight filters manage light diffusion.

They have a variety of functions:

- Giving a particular colour to a standard LCD display.

- Managing light diffusion from a display.

- To make LED backlighting consistent.

-

Surface protection

Surface protection -

Removable film is an essential scratch protection solution in many industries. Applying a protective film to a plastic surface will help prevent damage at any stage of your production process. Gravic, expert in printed and die-cut parts for professionals, is at your service to provide you with an electrostatic or adhesive film for the protection of your products. You can easily apply one of our protective films without any risk of damage to your products or adhesive residues on the surface.

Peelable film, designed to protect plastic surfaces from impacts, various marks or scratches, may be electostatic or adhesive, so that it can be repositioned without leaving adhesive residue on the support medium.

Peelable film is available in several colours and thicknesses, and can be applied to plastic items during the manufacturing process at removal from the mold. It will usually be removed by the end user.

SPECIFICATIONS

TYPES OF APPLICATION

- Smooth surfaces in automobiles (control panels)

- Plastic hoods with a gloss, enamel, satin or grained look

TYPES OF MATERIAL

- Electrostatic PE

- Removable adhesive PE

- Removable PE

Why should you incorporate removable protective film into your production processes?

A removable film is intended to protect plastic surfaces from shocks, marks or scratches during the protection and transport of the product as well as during its use by users. Accidents, even minor ones, are very common on an industrial production line, and can lead to product degradation. The impact of such events can therefore be mitigated or even nullified if you deploy the right protection solutions for your products.

We strongly recommend applying a scratch-resistant film to avoid negative feedback from your customers and partners, as it will protect your products at any stage of the process. Our electrostatic or adhesive films will not leave any marks on your products, and can be easily removed by customers on receipt if they wish. If removable films do not meet your specifications, please feel free to explore our full range of protective films to protect any part, such as an electronic device screen or a particular mechanical part.

Choose your protective film with Gravic

You can take advantage of the high-quality protective film available on our website in various colours and thicknesses. The removable film can be applied during the moulding process, for protection throughout the process, right up to removal by the end user. With Gravic, you can choose a high quality, durable scratch resistant film that is adapted to the specificities of your product or the subsequent treatments it will undergo on your production line.

Depending on your needs, you can choose between several types of materials and characteristics, from electrostatic adhesive film to masking film for industrial processing, for example. All of our protective films are treated for maximum ease of application and removal. For more information or for any particular request concerning our removable films, contact one of our experts for an exchange and we will get back to you as soon as possible.

-

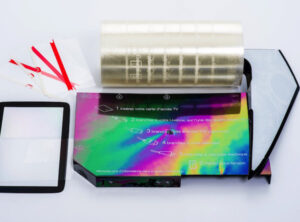

Multi-layer parts with finger lift

Multi-layer parts with finger lift -

Multi-layer protection films with finger lift are specialized protective films designed for use in various industries, including manufacturing, electronics, automotive, aerospace, and more. These films are constructed using multiple layers of adhesive-coated materials, with the addition of a convenient feature called a "finger lift." The finger lift is a tab or edge that makes it easier to peel off and apply each layer of the protective film without the need for additional tools.

In summary, multi-layer protection films with finger lift are advanced solutions that offer a convenient and efficient way to protect sensitive surfaces during various processes. The finger lift feature, along with the multiple layers and adhesive coatings, allows for controlled application and removal without compromising the protected surface.

Removable film is an essential scratch protection solution in many industries. Applying a protective film to a plastic surface will help prevent damage at any stage of your production process. Gravic, expert in printed and die-cut parts for professionals, is at your service to provide you with an electrostatic or adhesive film for the protection of your products. You can easily apply one of our protective films without any risk of damage to your products or adhesive residues on the surface.

Peelable film, designed to protect plastic surfaces from impacts, various marks or scratches, may be electostatic or adhesive, so that it can be repositioned without leaving adhesive residue on the support medium.

Peelable film is available in several colours and thicknesses, and can be applied to plastic items during the manufacturing process at removal from the mold. It will usually be removed by the end user.

Why should you incorporate removable protective film into your production processes?

A removable film is intended to protect plastic surfaces from shocks, marks or scratches during the protection and transport of the product as well as during its use by users. Accidents, even minor ones, are very common on an industrial production line, and can lead to product degradation. The impact of such events can therefore be mitigated or even nullified if you deploy the right protection solutions for your products.

We strongly recommend applying a scratch-resistant film to avoid negative feedback from your customers and partners, as it will protect your products at any stage of the process. Our electrostatic or adhesive films will not leave any marks on your products, and can be easily removed by customers on receipt if they wish. If removable films do not meet your specifications, please feel free to explore our full range of protective films to protect any part, such as an electronic device screen or a particular mechanical part.

Choose your protective film with Gravic

You can take advantage of the high-quality protective film available on our website in various colours and thicknesses. The removable film can be applied during the moulding process, for protection throughout the process, right up to removal by the end user. With Gravic, you can choose a high quality, durable scratch resistant film that is adapted to the specificities of your product or the subsequent treatments it will undergo on your production line.Depending on your needs, you can choose between several types of materials and characteristics, from electrostatic adhesive film to masking film for industrial processing, for example. All of our protective films are treated for maximum ease of application and removal. For more information or for any particular request concerning our removable films, contact one of our experts for an exchange and we will get back to you as soon as possible.

Screen protection foil, essential for protecting your products against breakage

Screen protection foil has various uses: mechanical treatment (sandblasting, shot peening), electrolytic treatment, paint application and holding objects in place when they are being transported or handled. This specific protection foil has been designed to counteract the problems typically encountered in these different usage areas: spillage, high temperatures or even automatic laying. In fact, it is also highly effective for general purposes such as holding objects in place when they are being transported or handled, as well as protecting against paint.

When choosing your protection foil, there are several criteria that you must consider first. Your screen protection must be carefully selected in accordance with what you are planning to use it for. Temperature conditions, mechanical stress or even the ease with which the foil can be peeled off are all decisive factors to bear in mind. To protect your surface during sandblasting, choosing the right thickness and support will allow you to optimise this protection. You should also ensure that your foil gives the appropriate coverage. If you want to protect parts of your products against paint, you must consider the temperature resistance and conformability of your film. The fineprotection ribbon is highly recommended for clean, perfect painting lines and it can be removed without leaving any unsightly marks.

Gravic therefore offers you a protection foil that will save you lots of time and produce impressive results in your line of industry. Just contact one of our experts to get a quote and they will get right back to you!

Protection foil for fragile objects

Unfortunately, accidents are all too common in production lines across various industries. It is therefore essential to choose the right removable foil to protect against any damage that could prove costly to your production chain. Gravic will therefore help you find a solution that is optimally tailored to your needs.

To protect your screens, the most effective solution is a screen protection foil. Gravic has an invisible version of this foil that you can use to protect against external sources of damage. The anti-scratch protection foil is extremely efficient at safeguarding surfaces from getting struck during manufacturing processes or product transportation. The foil also leaves no unsightly residues after removal. We recommend that you use a product type that helps solve the exact problem that you regularly encounter. Your products will then be guaranteed to be in an optimal condition when ready to be sold or used.

123, Zone Industrielle de l’Argile II, 06370

Mouans Sartoux, FRANCE

Tel. +33 (0)4 93 75 75 34

深圳市格瑞维克电子科技有限公司

深圳市南山区南山街道向南社区海德二道470号海德大厦A1002A

Shenzhen, CHINA