Bonding and Fixing

Home » Converting » Bonding and fixing

Bonding and fixing involves using specially designed tapes with adhesive properties to join or attach two surfaces together. These tapes are made of various materials, including foam, fabric, plastic, or even metal, with an adhesive layer on one or both sides. Adhesive tapes offer a convenient and versatile way to create secure bonds without the need for traditional mechanical fasteners like screws, bolts, or rivets.

Adhesive tapes offer benefits such as uniform stress distribution, vibration damping, and resistance to environmental factors like moisture and temperature. They can often simplify assembly processes, reduce the need for drilling or welding, and provide a cleaner appearance without visible fasteners. However, the choice of tape should be carefully considered based on the specific application’s requirements, such as adhesive strength, temperature resistance, and the type of surfaces being bonded.

-

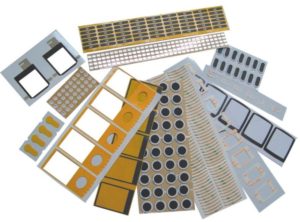

Double sided adhesives cut to shape

Double sided adhesives cut to shape -

Bonding and fixing with double-sided adhesives cut to shape involves using adhesive materials with adhesive coating on both sides to join or attach two surfaces together. These adhesives are typically pre-cut into specific shapes or sizes to suit the requirements of the application.

The process of bonding and fixing with double-sided adhesives cut to shape involves the following steps:

- Surface Preparation: The surfaces that need to be bonded or fixed together should be clean and free from dust, oil, or any other contaminants. Proper surface preparation ensures optimal adhesion.

- Selecting the Right Adhesive: Depending on the materials being bonded and the intended use, you need to choose the appropriate type of double-sided adhesive. There are various adhesive types available, such as foam tape, acrylic adhesive, rubber adhesive, and more, each offering different levels of bonding strength and characteristics.

- Cutting to Shape: Double-sided adhesive materials come in rolls or sheets, and they can be cut to the desired shape or size to match the specific requirements of the application. This step ensures that the adhesive fits the intended area accurately, maximizing the bonding efficiency.

- Application: Peel off the protective liner from one side of the double-sided adhesive and carefully apply it to one of the surfaces. Then, peel off the liner from the other side and press the second surface onto the exposed adhesive. Apply pressure evenly to ensure proper adhesion.

- Bonding and Fixing: Once the surfaces are joined, the adhesive forms a strong bond, effectively holding the two surfaces together. Depending on the type of adhesive used, the bonding may reach its full strength immediately or might require some curing time.

Bonding with double-sided adhesives cut to shape offers several advantages, such as:

- Versatility: Double-sided adhesives can bond various materials, including metals, plastics, glass, wood, and more.

- Aesthetics: Since the adhesive is hidden between the surfaces, it provides a clean and seamless appearance without visible fasteners.

- Easy Application: Applying pre-cut double-sided adhesives is a straightforward process, requiring minimal tools and expertise.

- Enhanced Performance: Some double-sided adhesives offer excellent bonding strength, resistance to temperature, and durability, making them suitable for a wide range of applications.

This bonding method is commonly used in industries such as automotive, electronics, construction, signage, and many other applications where a reliable, quick, and aesthetically pleasing joining solution is required

-

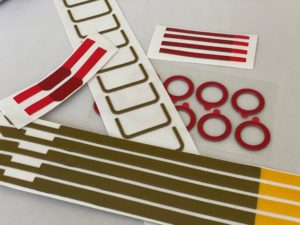

Foam tape, laminating adhesives

Foam tape, laminating adhesives -

Bonding and fixing with foam tape and laminating adhesives involve using adhesive materials designed for specific applications that require cushioning, vibration damping, or bonding irregular or uneven surfaces. Both foam tape and laminating adhesives are versatile and offer unique benefits in different scenarios.

Foam Tape:

- Foam tape is a type of double-sided adhesive tape with a foam core between two layers of adhesive coating. The foam core provides cushioning and conformability, allowing the tape to fill gaps and bond uneven surfaces effectively. Foam tapes are available in various thicknesses, densities, and adhesive types to cater to different requirements.

- Applications: Foam tapes are commonly used in mounting applications, where there is a need to attach objects to surfaces that might have slight irregularities. They are used in industries like automotive, electronics, construction, signage, and home improvement.

- Benefits: Foam tapes offer good adhesion strength, flexibility, and resistance to temperature and weathering. They can also provide vibration damping and help seal out dust and moisture when used in gasketing applications.

Laminating Adhesives:

- Laminating adhesives are designed to bond two substrates together to create a composite material. They are available in various forms, such as films, sheets, or liquid adhesives, depending on the specific application requirements.

- Applications: Laminating adhesives are widely used in industries like packaging, graphics, woodworking, textiles, and automotive for creating composite materials, laminating films, bonding layers, and other assembly processes.

- Benefits: Laminating adhesives offer excellent bonding strength and durability, providing a permanent and cohesive bond between substrates. They can be tailored to suit different materials, including plastics, metals, paper, fabric, and more.

Bonding and fixing with foam tape and laminating adhesives offer several advantages:

- Versatility: Both foam tape and laminating adhesives can bond a wide range of materials, making them suitable for diverse applications.

- Stress Distribution: Foam tape distributes stress and load across the bonded area, reducing the risk of material damage due to concentrated pressure points.

- Gap Filling: Foam tapes can fill gaps and irregularities in surfaces, creating a more secure and uniform bond.

- Damping Properties: Foam tapes can dampen vibrations and absorb shocks, making them ideal for applications where vibration control is necessary.

- Simplified Application: Both foam tape and laminating adhesives are easy to apply, providing a quick and efficient bonding solution without the need for additional tools or equipment.

When choosing between foam tape and laminating adhesives, it's essential to consider the specific requirements of the application, the materials being bonded, and the desired performance characteristics. Each adhesive type offers unique benefits and should be selected based on the intended use case.

- Foam tape is a type of double-sided adhesive tape with a foam core between two layers of adhesive coating. The foam core provides cushioning and conformability, allowing the tape to fill gaps and bond uneven surfaces effectively. Foam tapes are available in various thicknesses, densities, and adhesive types to cater to different requirements.

-

Conductive adhesives

Conductive adhesives -

Bonding and fixing with conductive adhesives involve using specialized adhesive materials that possess electrical conductivity properties. These conductive adhesives are designed to create reliable electrical connections between components or substrates while simultaneously providing a strong adhesive bond.

There are two main types of conductive adhesives:

Electrically Conductive Adhesives:

- Electrically conductive adhesives (ECAs) are used to create electrical pathways between conductive elements, such as bonding electronic components, attaching sensors, or connecting flexible circuits. They are particularly useful when traditional soldering is not feasible due to delicate components, temperature-sensitive materials, or specific design requirements.

- Applications: ECAs find application in electronics manufacturing, semiconductor packaging, printed circuit board (PCB) assembly, RFID tags, and other devices requiring electrical connections.

- Benefits: Electrically conductive adhesives offer good electrical conductivity, mechanical flexibility, and compatibility with various substrates. They can withstand thermal cycling and provide electrical stability over time.

Thermally Conductive Adhesives:

- Thermally conductive adhesives (TCAs) are used to dissipate heat from electronic components, acting as an alternative to traditional thermal pastes or pads. They provide both an adhesive bond and efficient heat transfer between heat-generating components and heat sinks.

- Applications: TCAs are commonly used in bonding heat sinks, power modules, LED lighting, and other applications where heat dissipation is critical.

- Benefits: Thermally conductive adhesives offer high thermal conductivity, reliable adhesion, and the ability to conform to irregular surfaces, ensuring efficient heat transfer and enhanced thermal management.

Key advantages of bonding and fixing with conductive adhesives include:

- Simplified Assembly: Conductive adhesives provide an alternative to traditional soldering or mechanical fastening methods, simplifying the assembly process, especially for delicate or heat-sensitive components.

- Damage Prevention: Conductive adhesives eliminate the risk of thermal stress or mechanical damage to components during the bonding process.

- Electrical Isolation: Conductive adhesives can create electrical insulation between bonded elements, preventing short circuits and unwanted electrical interference.

- Versatility: Conductive adhesives can bond various materials, including metals, ceramics, glass, and certain plastics, offering versatility in different application scenarios.

When using conductive adhesives, it's crucial to consider the specific requirements of the application, including the required electrical and thermal conductivity, the substrates being bonded, and any environmental or operating conditions. Proper surface preparation and curing procedures are also essential to ensure reliable and long-lasting electrical connections and adhesive bonds.

- Electrically conductive adhesives (ECAs) are used to create electrical pathways between conductive elements, such as bonding electronic components, attaching sensors, or connecting flexible circuits. They are particularly useful when traditional soldering is not feasible due to delicate components, temperature-sensitive materials, or specific design requirements.

-

High bond or LSE adhesives

High bond or LSE adhesives -

Bonding and fixing with High bond or LSE (Low Surface Energy) adhesives involves using specialized adhesive materials designed to create strong and durable bonds on surfaces with low surface energy. Low surface energy materials include materials such as polyethylene, polypropylene, PTFE (Teflon), and certain types of rubber, which are traditionally challenging to bond due to their non-porous and non-stick properties.

High bond or LSE adhesives are formulated with unique properties that enable them to effectively adhere to these difficult-to-bond surfaces, providing robust and long-lasting bonds. They are commonly available as double-sided tapes or liquid adhesives, each offering its own set of benefits.

Key features and advantages of bonding and fixing with High bond or LSE adhesives include:

- Superior Bond Strength: High bond or LSE adhesives offer exceptional bond strength, ensuring a secure attachment between the adhesive and the low surface energy material.

- Resistance to Environmental Factors: These adhesives are designed to withstand exposure to various environmental factors, such as temperature fluctuations, moisture, UV light, and chemicals, without compromising the bond integrity.

- Versatility: High bond or LSE adhesives can bond a wide range of materials, including plastics (e.g., polyethylene and polypropylene), rubber, composites, and metals, making them suitable for diverse industrial applications.

- Ease of Application: High bond or LSE adhesives are typically available in user-friendly formats, such as pre-cut tapes or easy-to-dispense liquids, making application convenient and efficient.

- Clean and Aesthetic Bonding: Unlike mechanical fasteners, these adhesives create a clean and aesthetically pleasing bond, without visible screws or rivets, improving the overall appearance of the assembly.

Common applications for High bond or LSE adhesives include:

- Automotive: Bonding plastic trim parts, side mirrors, emblems, and badges to automotive exteriors and interiors.

- Electronics: Attaching labels, touchscreens, and control panels to electronic devices.

- Signage: Mounting signs and graphics to various surfaces, including low surface energy materials.

- Packaging: Sealing and bonding packaging materials, such as cartons and boxes.

When using High bond or LSE adhesives, it is essential to ensure proper surface preparation. Cleaning the surfaces to remove any dirt, oil, or contaminants is crucial for achieving a strong bond. Additionally, following the manufacturer's instructions for curing or setting times is essential to maximize the adhesive's bonding strength and performance.

123, Zone Industrielle de l’Argile II, 06370

Mouans Sartoux, FRANCE

Tel. +33 (0)4 93 75 75 34

深圳市格瑞维克电子科技有限公司

深圳市南山区南山街道向南社区海德二道470号海德大厦A1002A

Shenzhen, CHINA