CONVERTING

Gravic is equipped with a full range of die-cut technologies

adapted to your applications.

Home » Converting

Technologies we use

DIGITAL DIE-CUTTING

Digital die-cut is perfectly suited to making prototypes and small series. This type of cutting uses a plotter equipped with a blade steered by a computer. This process offers a high level of flexibility, with precision cutting at +/- 0.15 mm with low fixed costs.

LASER DIE-CUTTING

Laser cutting can die-cut and engrave with precision and speed, for materials up to a thickness of 25 mm without burrs. Several Laser, YAG ou CO² sources can be used, depending on the materials. YAG is used especially for metals, CO² for plastic materials, plexiglas, polyester, wood, and other materials. This process offers cutting precision up to +/- 0.1 mm.

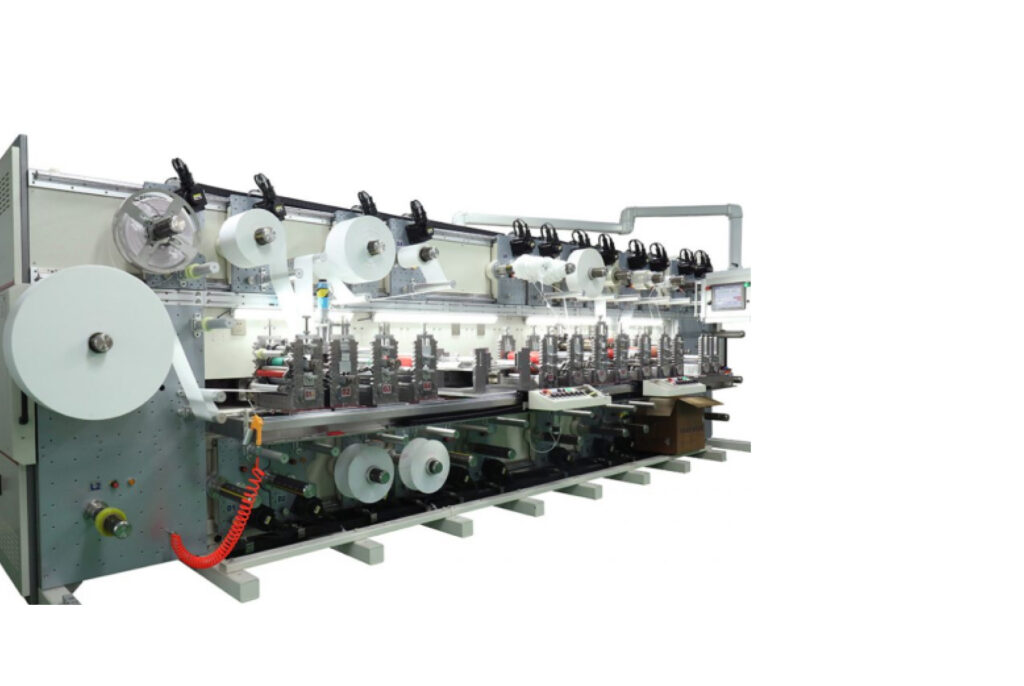

ROTARY

Semi-rotating or rotating cutting tools are used for medium to large series using materials of a moderate thickness. These may consist of magnetic cylinders with engraved cutting plates attached to them, or cylinders which are directly engraved with the form to be cut. These can be equipped with air expulsion systems to eject the cut parts, to prevent manual shelling operations. These tools have a cutting precision of +/- 0.1 mm and long durability. The high cost of these tools means that they are used for large production series.

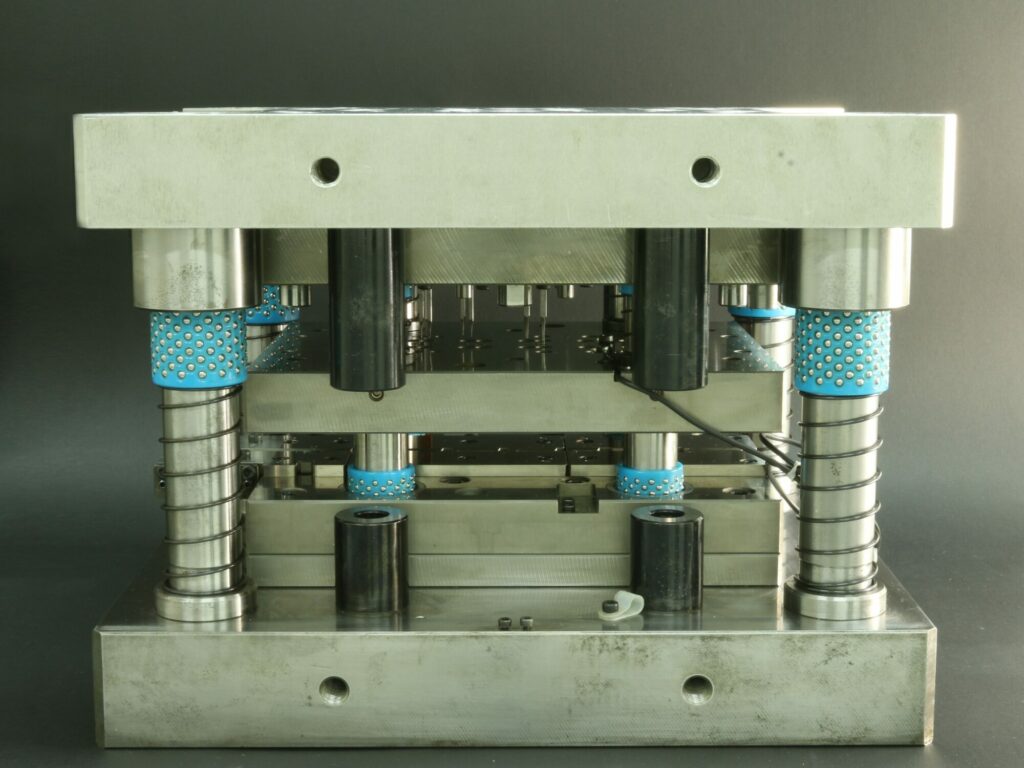

MATRIX PUNCH TOOL

Matrix punch tools are also used for large series, as well as for cutting of thick and hard materials (such as aluminium). These tools combine resistance and precision of up to 0.05 mm. The tools are appropriate to large volume products with a long life cycle, such as those found in the automotive sector.

Why trust Gravic to print your industrial technical labels?

With over 50 years of experience in technical printing and converting, Gravic offers a variety of marking, branding and identification solutions of the very highest quality. You will be sure to find the product that perfectly suits your specifications amidst our wide range of industrial labels: adhesive labels, engravable tags and labels, or 3D labels for identification and branding, security labels to combat counterfeiting and wear, or even electronic RFID tags to assure tracing of your products. Whatever your needs, don’t hesitate to browse through our website or contact us to find the perfect branding or labelling solution for you.

Gravic is much more than a mere label manufacturer: we assist you throughout the production process, including design, printing, cutting, and even lamination of your industrial labels. For example, if you are looking for easy-to-place adhesive labels, or if you are in need of technical labels which can withstand high temperatures and other environmental stresses, we custom-make your perfect labels, and we guarantee fast delivery in the packaging of your choice.

What other types of products does Gravic offer?

In addition to our industrial identification labels, we also offer die-cutting and printing of technical materials for a variety of uses. Our face plates and back plates can be used as housing and protection for your products, made of a stiff or flexible plastic plate; or for filters for display screens or automotive meters, we offer the full range of die-cutting and printing processes. On our website, you can also find protective and masking films to protect your products during shipping or in use, for example.

To meet your industrial needs for a protective or watertight seal or for electrical, acoustic or thermal insulation, Gravic has developed a range of die-cutting processes for specialist technical materials, such as gaskets, silicon foams, filters, or thermal pads. These essential items for the compliance and safety of your products are custom selected and die-cut in our workshops.

123, Zone Industrielle de l’Argile II, 06370

Mouans Sartoux, FRANCE

Tel. +33 (0)4 93 75 75 34

深圳市格瑞维克电子科技有限公司

深圳市南山区南山街道向南社区海德二道470号海德大厦A1002A

Shenzhen, CHINA