Biodegradable and antibacterial films

From nature to nature

Petroleum plastic film breaks down into micro plastic and pollutes our rivers, seas and oceans.

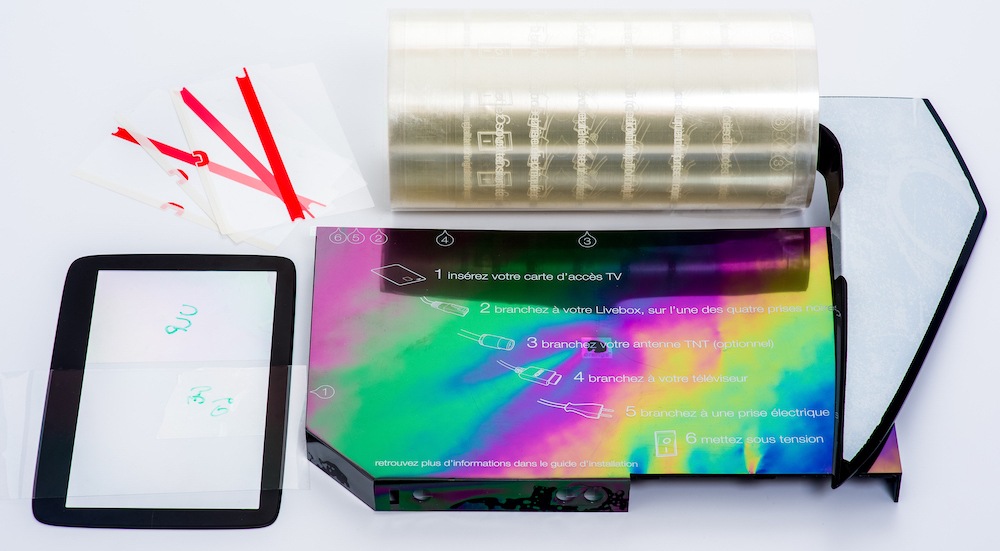

Poly Lactic Acid (PLA) film

Poly (lactic acid) or Polylactide (PLA) is a thermoplastic derived from renewable resources such as corn starch, tapioca or sugar cane. It is fully biodegradable and compostable. The bio-compostability of the PLA films used by the Gravic Group depends on the temperature and humidity and is estimated as follows:

- In Compost (58±2℃, >50% RH, Aerobic) – 6~14 weeks

- In Landfill (Semi-aerobic) – 2~4 months

- In Water & Soil – 2~3 years

- In Atmosphere – 5~10 years

How is PLA film created?

The fermentation of starch (dextrose) yields two optically active enantiomers, namely D (-) and L (+) lactic acid. Polymerization is carried out by either direct condensation of the lactic acid monomers or by ring-opening polymerization of the cyclic diesters (lactides). The resulting resins are converted into films and sheets via standard forming methods including injection and blow molding.

Where is PLA film used?

PLA is mainly used in the packaging industry for cups, bowls, bottles and straws. Other applications include disposable bags and trash liners as well as compostable agriculture films. PLA is also an excellent choice for biomedical and pharmaceutical applications such as drug delivery systems and sutures because PLA is biodegradable, hydrolysable and generally recognized as safe.

Gravic offers two types of PLA films:

- Clear mono-layer PLA film with Anti-static coating (BC11C), which is used in envelope windows, paper lamination and glitter metallisation.

- Clear 2-layer PLA film with heat sealable PLA layer (TE90), which is used in packaging of fresh food with short shelf life (fruit and vegetable, sandwiches, cakes, muffins etc)

Gravic’s PLA films are environmentally-friendly:

- 100 percent biodegradable and compostable

- break down into CO2, water and soil nutrients

- leave no harmful components when buried in the ground

- contribute to the reduction of plastic pollution and Green House Gasses (GHG)

Surfaces covered with PLA films help kill or inhibit the growth of bacteria, thanks to their high antibacterial (Staphylococcus aureus ATCC 6538P, Escherichia coli ATCC 8739, Klebsiella pneumoniae ATCC 4352) properties as well as high durability and hard coating.

The antifouling properties of the PLA films help slow the growth or facilitate detachment of subaquatic organisms that attach to the hull and can affect a vessel’s performance and durability.

What are the properties of PLA films?

The properties of PLA like melting point, mechanical strength, and crystallinity depend on the proportions of the D(+) and L(-) stereoisomers in the polymer and on the molecular weight. As for other plastics, the properties of PLA films will also depend on compounding and on the manufacturing process.

Films made of PLA are amorphous or semi-crystalline and have:

- very good clarity and gloss,

- little or no odor,

- very high moisture vapor transmission,

- very low oxygen and CO2 transmission rates,

- good chemical resistance to hydrocarbons, vegetable oils, and the like.

Gravic’s PLA films have excellent mechanical properties, such as good heat stability and superior optical properties. Overall, the mechanical properties of PLA are very similar to PET. However, typical PLA grades have a lower maximum continuous service temperature and are more brittle. Often plasticizers are added which (greatly) improve its flexibility, tear resistance and impact strength (pure PLA is rather brittle). Some novel grades also have much improved heat stability and can withstand temperatures up to 120°C (HDT, 0.45MPa). The heat performance of general purpose PLA is typically between LDPE and HDPE and its impact strength is comparable to HIPS and PP whereas impact modified grades have much higher impact strength comparable to ABS.

Get in touch to work with us

Contact us to request technical data sheets and to explore ways we can help you with your project.

We are grateful for our close collaboration, and we are committed to continuing to evolve and progress to meet your requirements!

Improve your life with Gravic!

Share this post: